Small CNC Machines: How They Make Manufacturing More Efficient These small designs provide accuracy and speed to allow businesses to gain this as standard, ensuring that they can save time and money without losing the sharpness of print.

Small CNC machines from a provider such as DAS are intended to make production easier by automating tasks that were formerly done by hand. Such automation minimizes the likelihood of errors and allows for faster product manufacture. For instance, tiny wallet-sized CNC milling machines can cut millimeters from most materials in seconds and does so with almost no errors compared to the old hand tool approach. Moreover, they do not stop, neither do they require pauses – this only increases their productivity in the longer term. Small CNC Machines can streamline your workflow and make you more efficient.

Small CNC machines are affordable, and that is one of the advantages they offer over large ones anywhere in the world. DAS Offers variety small CNC machining services to fulfill different types of manufacturings you want without hurting your budget! For example, a mini C NC lathe is capable of precision cutting for making products that are small and efficient. They are also small, and require very little floor space in a crowded manufacturing environment. Affordable small CNC machinesThere is a lot of press in the machining world about larger and more expensive machining centers due to their ability produce larger parts with better tolerances, for example, portable CMM.

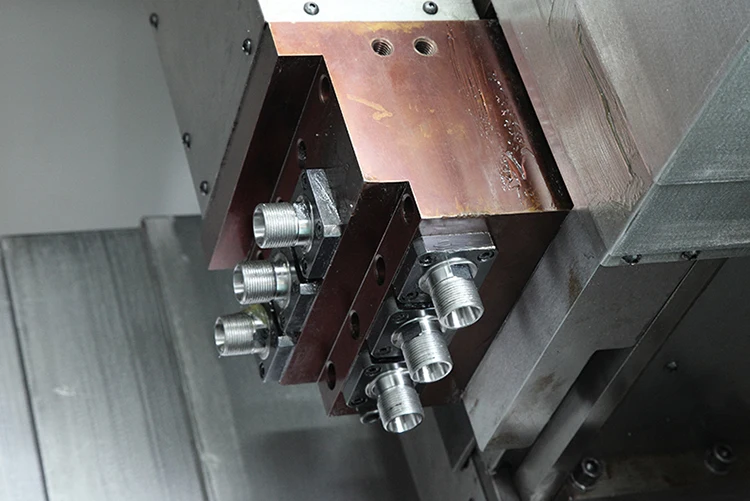

Small CNC machines are great tools for precision machining, but they can also introduce some not-so-wanted qualities. One typical problem is lack of stiffness, leading to their vibrating and obtaining an incorrect final shape. This is compensated for by choosing a strong material and appropriate calibration. Another problem is that the work space can be limited, which may limit the size of workpiece that may be machined. It is highly recommend that users need to check the size of machine firstly before purchase. Furthermore, the cutting speed of a small CNC machine may be slower than that of a larger machine so you should have patience with your work and plan accordingly if necessary. Swiss Type CNC Lathe

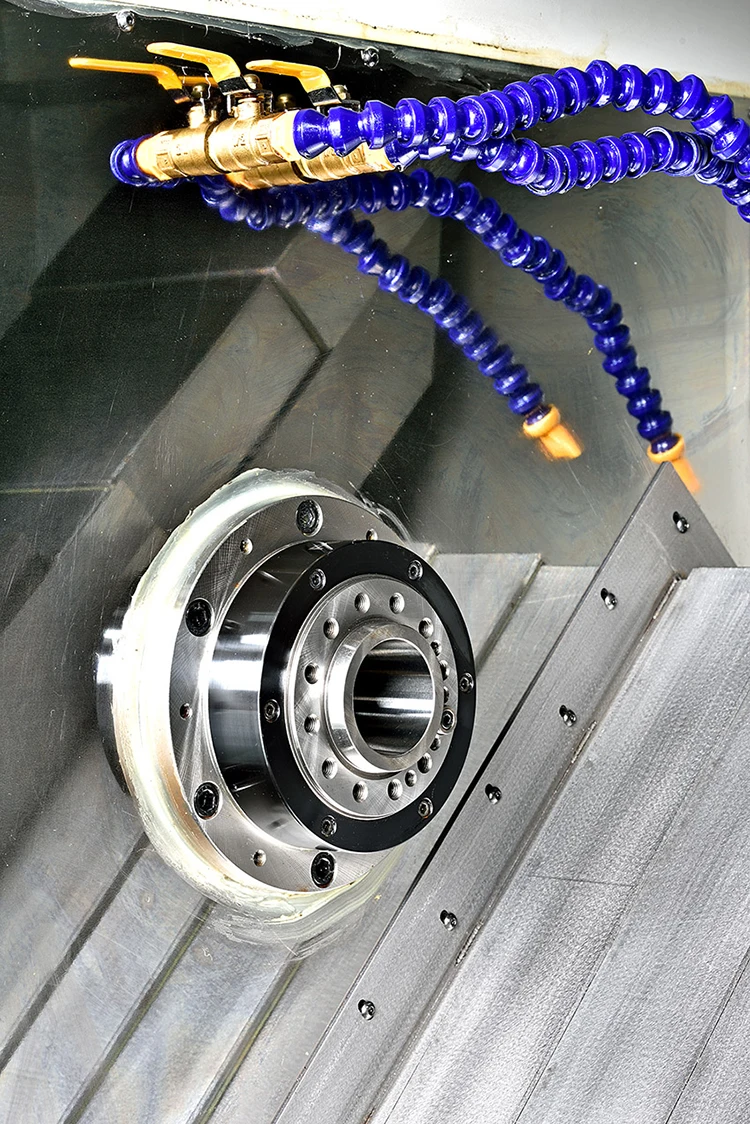

There are a few things you should consider when shopping for a small CNC machine to make sure that you get the best one for your needs. 1–First, how much space does the equipment take up and do you have room in your workshop. Also ensure the machine is of a size suitable for machining the workpieces you intend to machine. Then, check out the spindle speed and cutting ability of the machine. Faster spindle speeds and cutting capabilities to reduce cycle time will enable faster and more accurate machining. Also consider machines with easy-to-use software and controls, for more user-friendly operation. Last, but not least, think about the budget and find some machines that can provide you with what you most want for your money. Flat Bed Gang Type CNC Lathe

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved