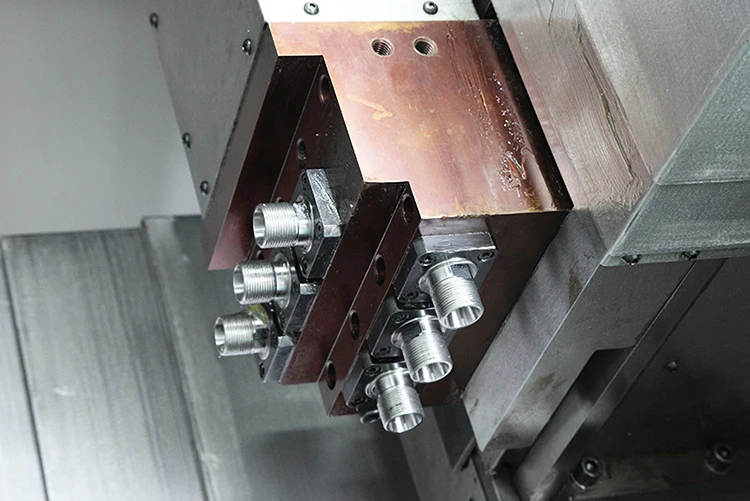

Dual turret turning with two turret:

The twin turret lathe technology has gathered significant attention in the industrial manufacturing process and in DAS company. This high technology equipment make the production efficient which will make it potentially increase productivity and lower manufacturing cost. With two turret lathes have multiple operators but in the same amount of space if you need multiple pieces it can reduce production time and lead to quicker turn around. This is not only good for our company, also allows us to meet the increasing requirement of our client accurately and timely.

Manufacturing and Wholesale PRECISION is a premium in the manufacturing sector, especially for wholesale buyers whose goal is to provide customers with the highest quality products. We know the quality of precision machining and therefore we have a committed to the latest dual turret lathe technology at DAS. Thanks to this state-of-the-art machinery, we are able to offer an unmatched level of precision and quality to our wholesale buyers of parts. Our dedication to quality machining is what sets us apart from the rest of the market and establishes a confidence with wholesale customers that they will always receive the highest quality.

One of the greatest benefits of dual turret lathes is the much higher productivity. At DAS our investment in dual turret lathe technology has resulted in cost savings and higher production volumes in less time. We use the double spindles and turrets in our lathes to do multiple pieces at once so there’s less down time and we can produce more. Not only does this give us a productivity boost to our bottom line, we’re able to fulfill orders quicker and more efficiently than ever before.

Quality and affordability are two cornerstones of the manufacturing industry, two things at which DAS also happens to excel. With both of our turrets, our dual turret lathe technology helps us to maintain high quality of the products that we produceomechanizedmachiningA mit we want to use our dual turret lathe technology to manufacture a mit because mit is a big and important component that hold the helmet and it's a critical part of the helmet so for they we want to use dual turret lathe technology for optimum machining. Such high quality meets and exceeds all OEM specs, ensuring our customers receive the best valves available on the market. Furthermore, our dual turret lathes are very efficient, and therefore, we can offer cost-effective long-term solutions to our customers, as it gets cheaper to produce the equipment the faster we build it. Through provid-ing high quality and low cost solutions, different from others, we are recognized to be a trustworthy partner to support worldwide customers with their manufacturing projects.

In the competitive world of today, it's the lead edge technological applications which determine who is a step ahead, and at DAS, the double turret lathes make the difference for us. By making parts faster, more precision, and cheaper than a regular lathe we are part of the industry lead. Our significant investment in dual turret lathe technology has enabled us to quote the most competitive price points while reducing lead time and assuring the highest quality of materials and workmanship, making our customer case over other manufacturers undeniable. Our dual turret lathes have helped to make us a leader in our industry as your go-to source for all of your manufacturing needs.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved