One of the biggest benefits to using Swiss CNC lathes is that you can create very complex and intricate part designs with extreme accuracy. These machines are controlled by computer numerical control (CNC) which mean that they follow specific set of instructions and make consistent and precise part every time. This level of accuracy is very important in sectors that use it for example aerospace and medical where any small mistake can be catastrophic. Also swiss cnc lathes are highly production as well as fast cycling times. This allows maximum throughput of parts in minimum time, making tight deadlines possible and increasing overall productivity. In addition, Swiss type cnc lathe machines could allow for several operations in one set up. This require less manpower step and will result in less error, and to produce higher quality of end products. Ultimately, the benefits of Swiss CNC lathes make them a worthy investment for companies that want to upgrade their manufacturing capabilities.

Reputation, experience and capabilities So how do you find the very best Swiss CNC lathe suppliers? Reputable suppliers tend to offer quality machines and good customer service. Moreover, a successful supplier will be very well versed in the technology and able to provide invaluable advice and assistance. And it is important that you select a supplier that has resources to fulfill your requirements. If you need tuning, training or ongoing maintenance, adding a supplier that provides all these will ensure the successful and seamless integration of cnc swiss lathe machines in your business. In addition, you can research online, visit trade fairs and hear about Switzerland CNC lathe suppliers through word of mouth from colleagues. Through intensive research and by factoring them, the solution will easily direct you to the right supplier that helps to cater for all your manufacturing requirements.

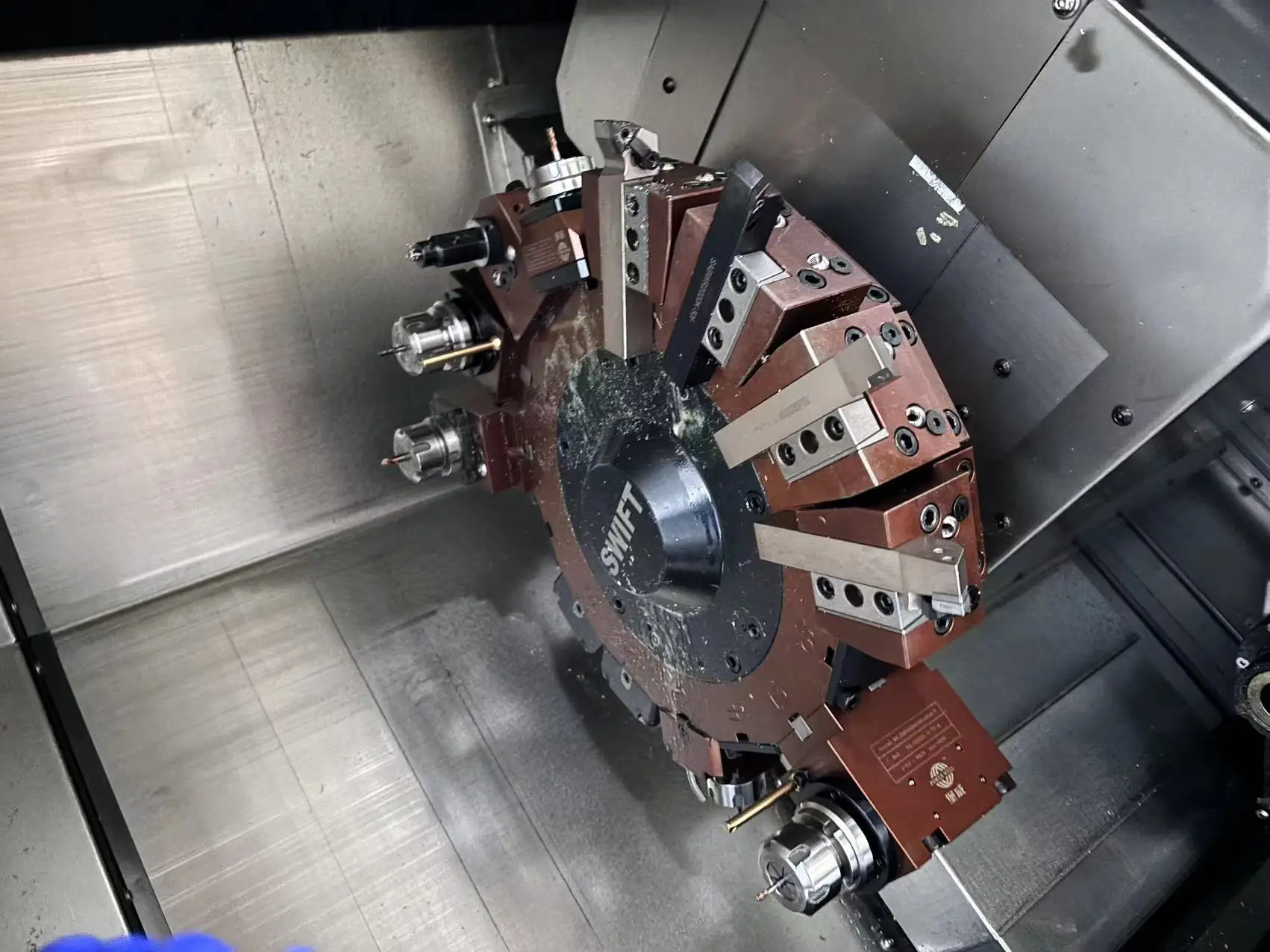

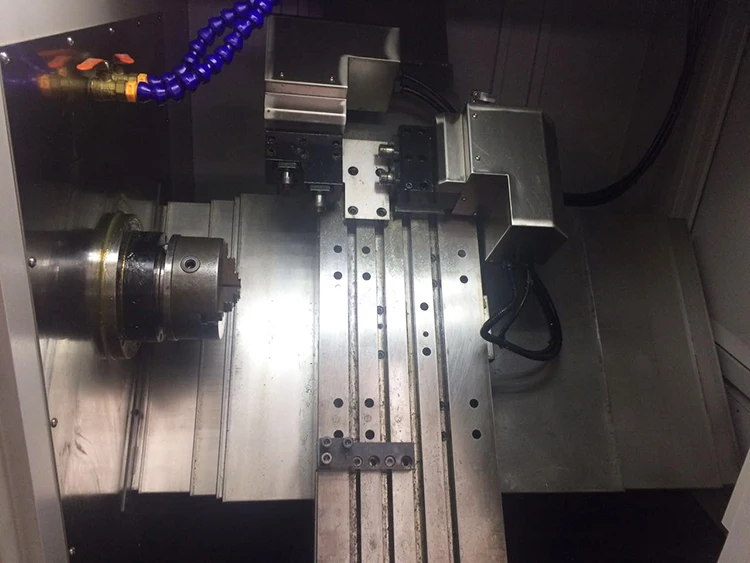

Our Swiss CNC lathes incorporate state of the art technology to assure our highest degree of accuracy in machining those hard to make parts. Equipped with live tooling, sub-spindle capacity, and high-speed machining There is very little that our swiss lathe for sale do in terms of precision machining capabilities.

When you select a DAS Swiss CNC lathe, you are assured of receiving a high-quality machine tool that will enhance the productivity and quality while significantly reducing production costs. View our Swiss CNC lathes and contact us to get the machine that will be in any way as useful for your machining opportunities.

Though highly-precise and reliable, Swiss CNC lathes some common problems can occur which may compromise both the working output and efficiency of the machine. Tool wear is one of the most typical problems in achieving a desirable surface finish and dimensional accuracy. Therefore, high quality cutting tools must be used and often checked for wear to avoid damage.

Chip control is another challenge found with Swiss CNC lathes. Chips can accumulate in the machine and cause cutting interference with this resulted in poor machining quality. It is important to apply a right chip control technology, e. g., selecting appropriate cutting conditions and removing chips frequently.

When it comes to Swiss machines, there are quite a few of these machine manufacturers who promise better quality, performance as well as stability, with time passing by. Top 10 best Swiss lathe manufacturers from China, because it has a broad selection for different machines, so many industries have the room to choose their own motor product.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved