Swiss screw machining is a unique method for manufacturing small, intricate components. We at DAS apply this method to make critical parts which fit in machines such as aircraft and medical instruments. Thanks to our sophisticated equipment and expert workers, we can produce these infinitesimal parts extremely quickly and just exactly right. That’s a great way for companies to acquire what they need without waiting a long time or spending too much money.</p>

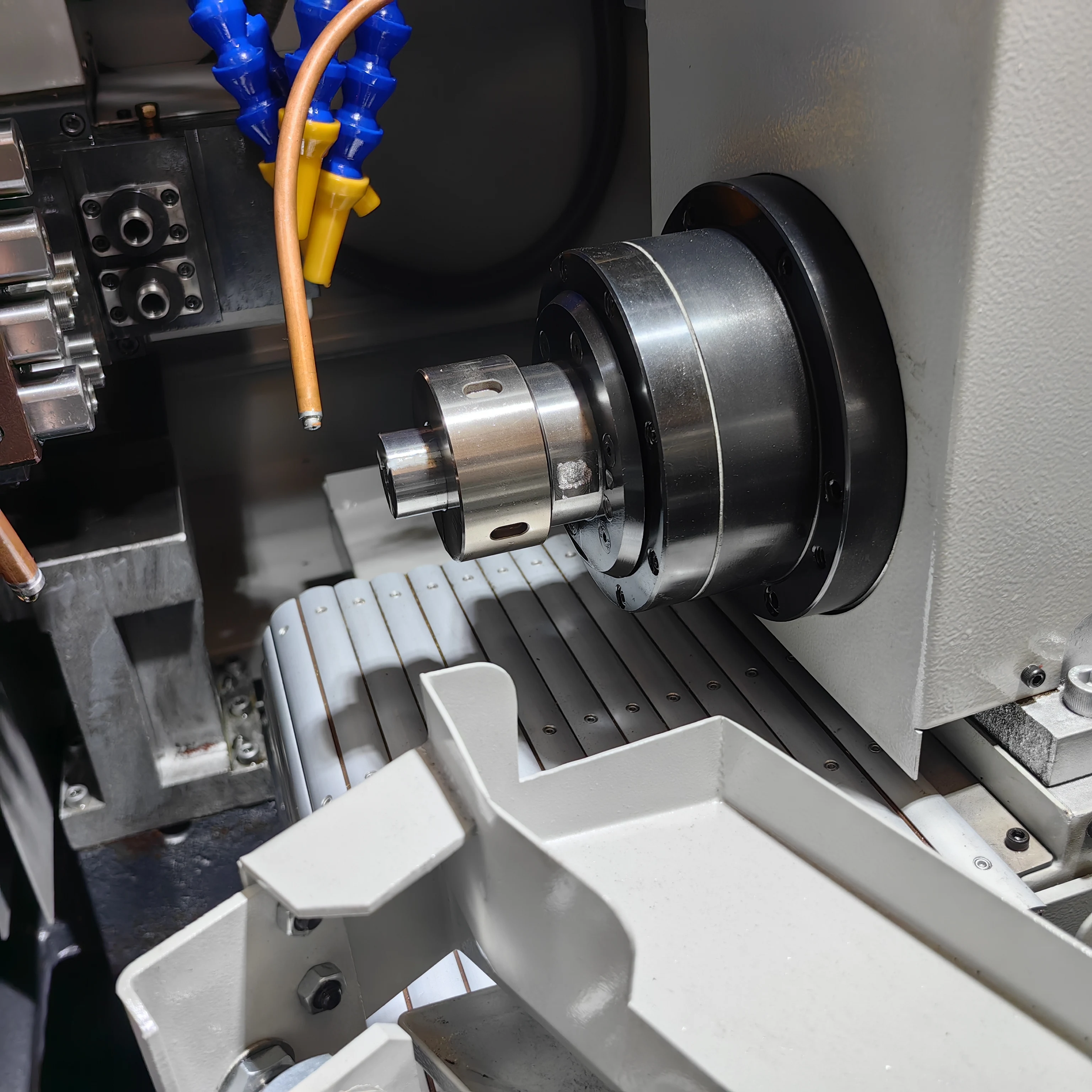

At DAS, we specialize in super precise parts with Swiss screw machining. This all allows us to work on small pieces with a ton of detail. We can make parts, for instance, that are critical to things like watches or medical instruments. We control the process so closely that every part comes out just right, which is very important for our customers because they require perfect parts for their products.</p>

There's zero margin for error in fields like aerospace and medical. That’s why here at DAS we offer custom CNC Swiss machining. That means we can create parts that are incredibly specific to their needs, taking full advantage of our high-tech machines and technology. Our team has collaborated with customers to figure out what they need, and now we make parts that slot neatly into their big projects — airplanes or medical devices, say.</p>

We know that time is money. Here at DAS things move fast, including getting your precision Swiss machined parts into your hands. When we receive the orders, our factory is poised to start working on them. That quick start and our streamlined process and process efficiencies allow us to make and deliver parts faster than the bulk of companies out there.</p>

Purchasing in volume can also be costly. But at DAS, we’ve found a way to make it more affordable. We have wholesale pricing for bulk or large-quantity purchases for those who need a lot of parts at once. Our Swiss screw machining operation is built to crank out large volumes of parts fast, and the quick turnaround time can help to keep cost low. That makes it easier for buyers to obtain the high-quality parts they need without spending a fortune.</p>

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

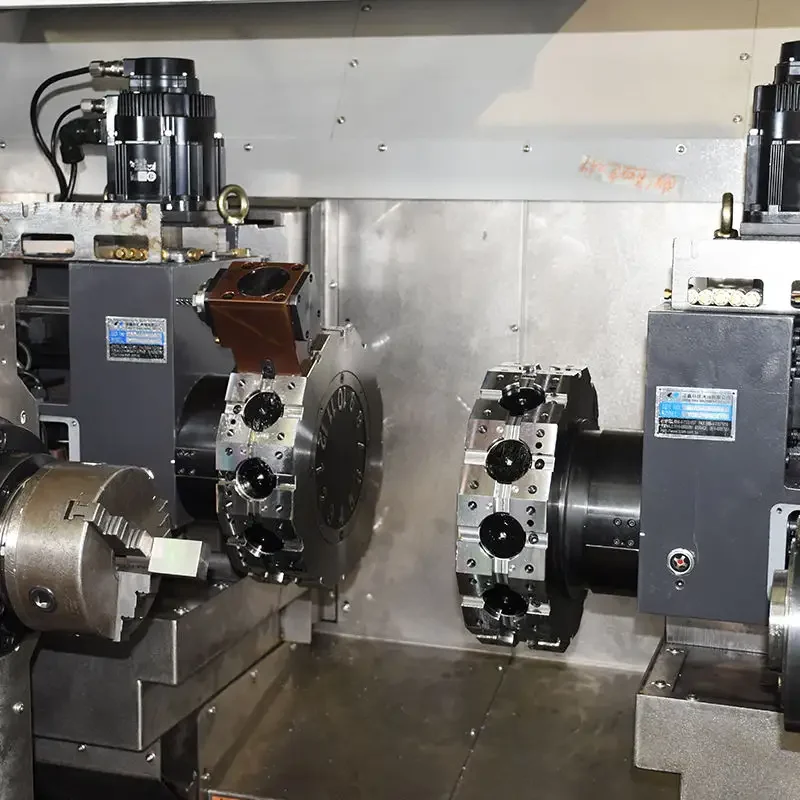

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved