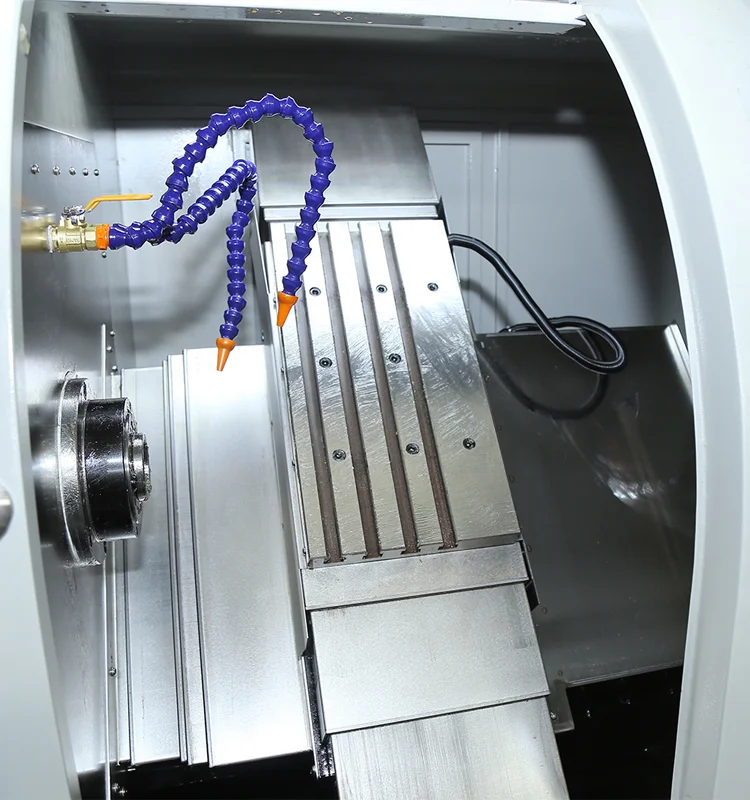

One of the major benefits of having a horizontal mill with its axis is the versatility. A horizontal milling machine is versatile and can be used for metal shaping, hollowing out, cutting or shaving the edges of the workpiece. Such flexibility allows the production of intricate parts and components, with precision and efficiency. Moreover, horizontal mill-axis machines are known for their ability to process large workpieces, which is particularly relevant in industries such as aerospace and automotive where size and scale play an important role.

Better finishes - Horizontals do have more favorable chip control which can result in better surface finishes. Horizontal milling machines can generate accurate and smooth surfaces on work pieces in conjunction with high-quality grinding equipment, and give all of our clients the benefit of these powerful machines. This is a must have for parts with critical tolerances and fine surface finish.

Horizontal mill axis is an important part of good quality output and it also saves the debugging moment deviation. With state-of-the-art and high-level technologies, the flexibility of horizontal milling machines is unparalleled. Such level of the exactitude in the scanning is very important to keep the quality check on along with from manufacturing.

Horizontal mill axis machines also provide better repeat accuracy, which means it is easier for manufacturers to make the same part over again with high precision. This guarantees each product is made to the specific standards and quality requirements on our production lines, resulting in a customer experience they can trust.

Moreover, the horizontal mill axis quality is controlled by thorough testing and examination procedures. Manufacturers will check the quality for every step in the process to eliminate defects of products. The dedication to quality control aids in staving off defects and that only superior products are sent out for customers.

horizontal axis mill has many advantages, and it's a vital part in guaranteeing quality work in industry. Through the use of horizontal milling machines, companies are able to cut down on waste, conserve resources and maintain a high degree of structural integrity in their final products. The end result is a product that delivers reliable performance while satisfying the needs of clients.

There are a few common issues which can be encountered when using horizontal mill alignment. One problem is that the axis was not aligned, which may cause imprecision of milling. This may be due to misplacement or damage of the device. Another issue is vibration, which may lead to poor surface finish and short tool life. To avoid these7,8 problems it is necessary to carry out regular maintenance and the axis of rotation calibration. Furthermore, when high quality cutting tools and good machining techniques are used this ensures that difficulties are kept to a minimum and the horizontal mill axis operation will function well.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved