High precision CNC machining Manufacturing precision components are widely used in industries such as aerospace, automotive, medical instruments, electronics, prototyping, etc. At DAS we know how crucial precision and dependability are when it comes to manufacturing and this is why we are dedicated to producing the best CNC machined parts for each application. Let’s have a look on how our precision Swiss Type CNC Lathe with Double Spindle Swiss Type Machine services meet the distinct needs of diverse industries.

When under pressure, there is no room for error in the aerospace industry. With our ultra-high precision CNC machining, we are able to create complex components with precise tolerances that adhere to the exacting demands of the aerospace industry. From parts for engines to parts for the structure of the aircraft, our machining is precise to keep your components on the move.

In the automotive sector, high-precision mechanical components are crucial to the quality and safety of cars. At DAS, we manufacture high-quality, CNC machined parts designed to meet your unique specification for any automotive application. Whether it is engines’ parts or transmissions parts, or complex electronic systems, our CNC services provide precision engineered parts which contribute to better performance and fuel efficiency of cars.

These Tautie reels are also designed maximized for the production and assembly needs of the medical device manufacturing and assembly of it's products.

There is no room for errors in medical device manufacturing. We are a precision CNC machine shop that caters to the medical industry, and we guarantee that each of our parts will meet the most demanding specifications for precision and reliability. From surgical tools to implant devices, our CNC machined medical devices are built to meet the most precise specifications and further technology in healthcare.

In the rapid-paced industry of electronics it is critical to provide custom solutions to accommodate the ever-changing demands of consumers. Our bespoke CNC machining services are tailored to meet the needs of the electronics sector, providing precision components, and unique components for an application. From circuit boards and connectors to housings, our CNC machining options can deliver the precision and tolerances to control modern electronics and technological innovation.

When it comes to prototyping and production, reliability and efficiency are the make or break factors. We're synonymous with quality when it comes to our CNC Precision Machining and weve helped a countless number of businesses take their creations to the next level. From prototype to volume production we can offer you precision CNC machining to meet your needs for high quality components with on time deliveries. Our focus is to help our customers bring their products to market faster and more efficiently.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

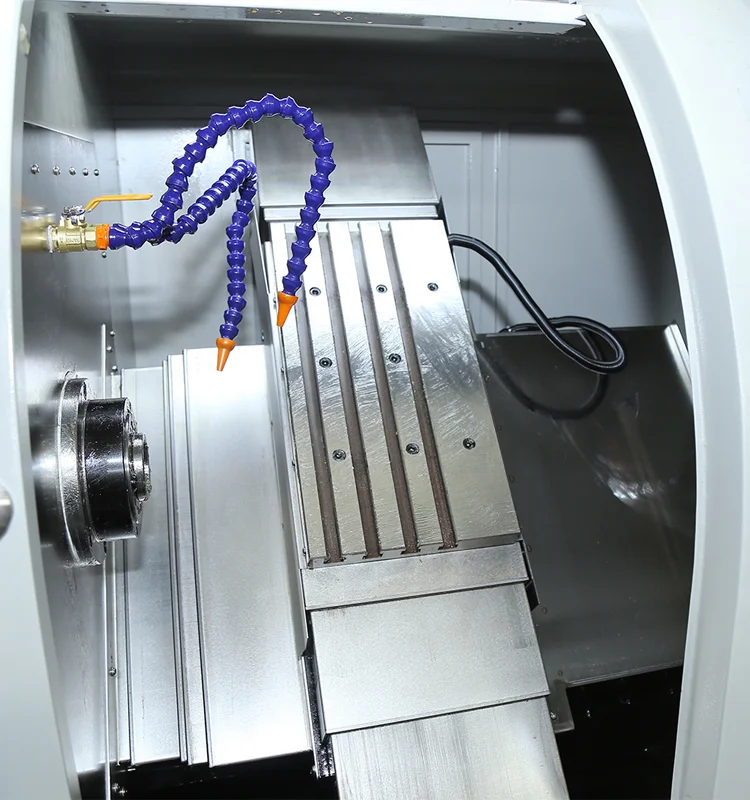

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved