Milling is a type of machining that cuts and shapes materials with the use of a milling center machine. At DAS, we machined components and products for a number of industries using state-of-the-art milling centers. These centers have tools that can work with all sorts of materials, from metals to plastics. We need milling centers in order to produce a top-notch product to meet our customers' unique requirements.

At DAS, we have the most precise milling centers. This is all super important for industries in which even a small mistake can lead to some big problems, like in aerospace or medical devices. It’s the opposite, in fact: Our machines can mold materials with precision so that each part fits perfectly in its place. And we know that accuracy matters, so we consistently ensure that our machines are simply the highest-precision best running equipment available.

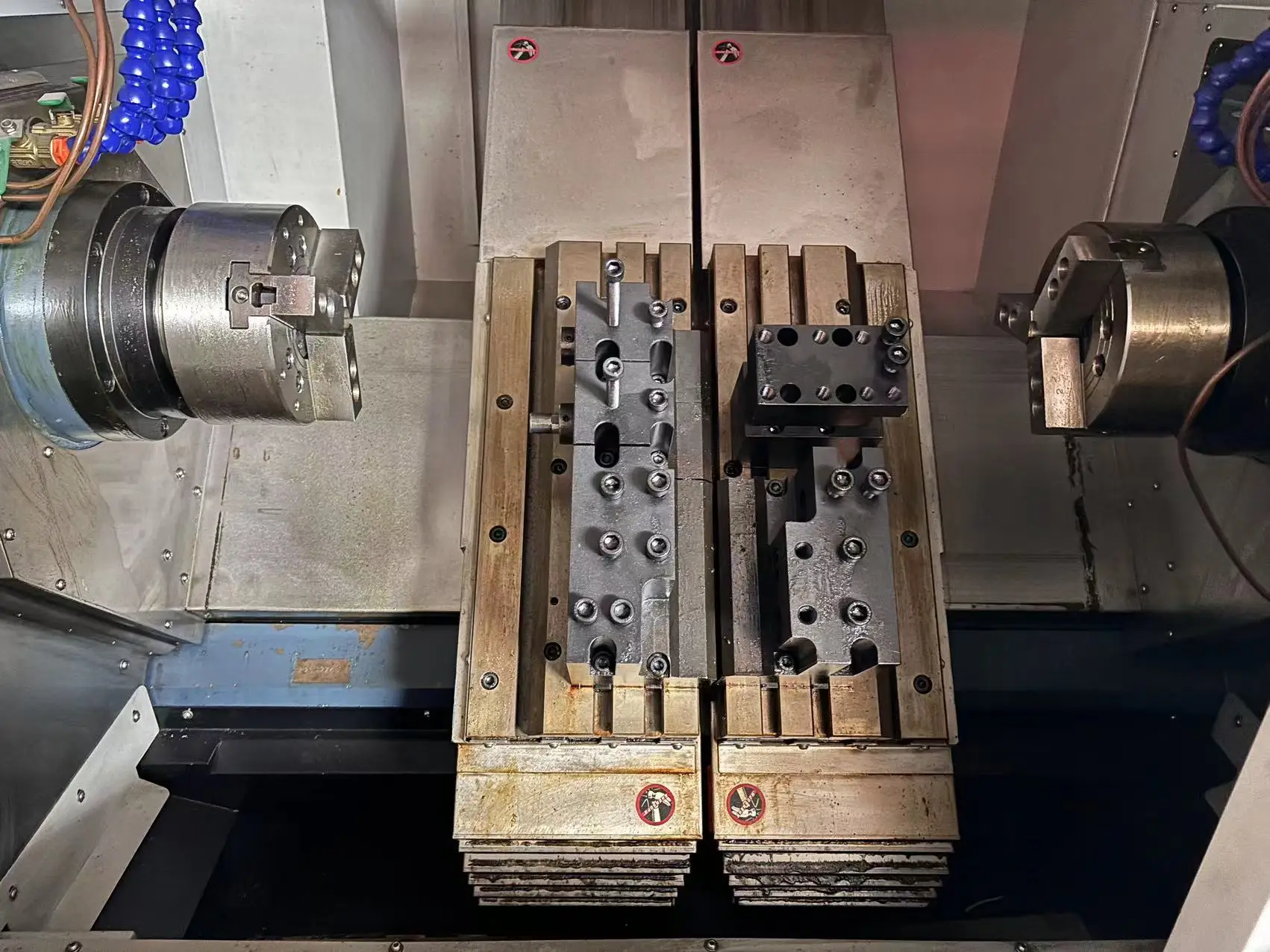

At DAS we have the best in technology for milling centers, to ensure that we can do the absolute best work possible. We now have machinery that can move more quickly, and form more complex shapes, than at any time in history. This technology enables us to ensure that we can handle any project, no matter how complex, while also producing the best possible outcomes. We continue to update our machines and train our staff to use the latest and best methods.

Quality is a big deal at DAS. We inspect the hell out of anything we make in order to ensure it’s just right. Our milling centers are equipped with sensors and software that are specially designed to inspect the quality of every piece that we produce. If something is wrong, we learn about it immediately and we fix it. In this way, we double check that everything we send to our customers is the best and they can depend on our products.

Each customer is unique, and sometimes they want something that has never been made before. At DAS, we live for challenges like this! With our milling centers, we have the capacity to produce everything from precision rovings to very special product constructions. We are driven by our customers — not the other way around — and are constantly working to make what our customers expect. Whether it is an unusual shape or something that is difficult to work with, we really help them get exactly what they want.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved