It is a method that is essential for producing parts with foucs to customer's specific requirements & precise specifications of industries. At DAS, we realize the need for precision machining in industry. We meticulously design by utilizing our high precision CNC center for that perfect part each and every time to exceed all of our clients’ needs with the best in quality products.

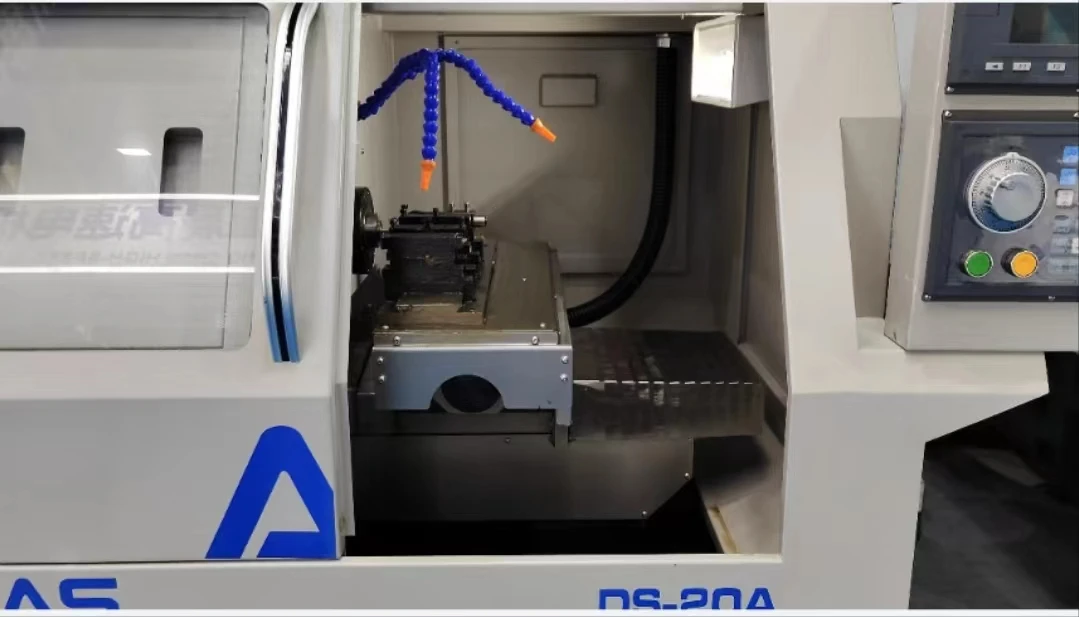

State of the art technology and cutting tools on our CNC center, enable precision machining with the highest quality. Our skilled machinists rely on their own expert knowledge to machine intricate designs and narrow tolerances, and take pride in delivering flawless parts. Everything is carefully considered, from the design right through to the final product to ensure the highest standards are achieved. With precision machining at our fingertips, we are able to make parts that meet and exceed industry standards, providing our customers with success.

Our CNC center’s work range is very complete, giving you great flexibility for your manufacturing product. Whatever industry you in – automotive, aerospace, medical, you name it – we offers CNC machining services that match all levels of requirement. From rapid prototyping to production runs, our shop has the capacity to mill and turn a wide variety of materials, size ranges, and complexity levels, and thus are ready to be your manufacturing partner regardless of market. This flexibility lets us fully accommodate the specific requirements for your industry, providing each business with a custom made solution that progresses success and development.

We know that on the production line in the industrial manufacturing industry, schedule is all. That is why, at DAS we focus on quick turnaround times, to guarantee that our clients get their parts when they need them. Our well defined procedures and processes, well oiled work process help us to Ac and reduce lead time and produce schedules without compromising on quality. Due to our CNC center capacity, we are able to respond to quick orders and provide quality parts in short lead times in order to keep our customers ahead of their competition and cope with market needs.

Businesses have no other choice but to consider cost-effectiveness of everything from their manufacturing techniques to their bottom line. We are not the lowest priced CNC Machining provider, but we are a smart investment in terms of product quality, strong delivery performance, and competitive pricing to ensure we can provide products that meet budget constraints. Our cost is second to none, without sacrificing any level of quality. It is not, rather it is to ensure that with us you get perfect materials, our clients get the best quality material, with us HAVE WON the heart of thousands of customers, become the most preferred and best business partner in the field of metal supply.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved