Heavy& nbsp; Duty CNC Lathe Machine DAS& nbsp; brand heavy duty Cnc& nbsp; machine& nbsp; is designed to work at extreme tolerance.Daslathe& nbsp; used in connected& nbsp; industries like aviation, automotive, commercial & mechanical.& nbsp; These are all metal construction& nbsp; machines and are built& nbsp; with the highest quality materials.& nbsp; Featuring& nbsp; industry-leading technology, these machines& nbsp; are renowned& nbsp; for their& nbsp; precision and& nbsp; reliability;& nbsp; offer& nbsp; a& nbsp; sturdy construction and can& nbsp; easily& nbsp; be integrated in& nbsp; your& nbsp; manufacturing facilities.

& nbsp;The DAS heavy-duty& nbsp; CNC& nbsp; lathe machines employs the high& nbsp; quality& nbsp; material which& nbsp; is& nbsp; durable and sturdy. From& nbsp; robust& nbsp; construction to assured quality, everything& nbsp; is designed especially for industrial usage. These machines& nbsp; have been& nbsp; designed& nbsp; to be structurally stable and& nbsp; reliable even in the most& nbsp; demanding working& nbsp; conditions. Through the application of quality materials and close& nbsp; attention& nbsp; to& nbsp; detail,& nbsp; DAS can be sure that their& nbsp; CNC& nbsp; lathe& nbsp; will offer the steadfast performance that is expected& nbsp; in& nbsp; the most& nbsp; demanding production environments.

& nbsp;Furthermore,& nbsp; the finely-tuned design of these machines makes them both& nbsp; long-lasting as well as simple to maintain. To& nbsp; keep CNC& nbsp; machines working well and to maintain& nbsp; their& nbsp; efficiency,& nbsp; regular& nbsp; attention is necessary. DAS recognizes this requirement,& nbsp; and& nbsp; build& nbsp; services into their& nbsp; machines& nbsp; which keep maintenance quick and trouble-free.& nbsp; It’s this long-term commitment& nbsp; to durability and easy of use that puts& nbsp; DAS& nbsp; in a league of their own when it comes to industrial manufacturing& nbsp; systems, and makes their CNC lathes big rig machines& nbsp; a& nbsp; wise investment for& nbsp; any& nbsp; company looking to expand& nbsp; upon its& nbsp; existing machining capacities.

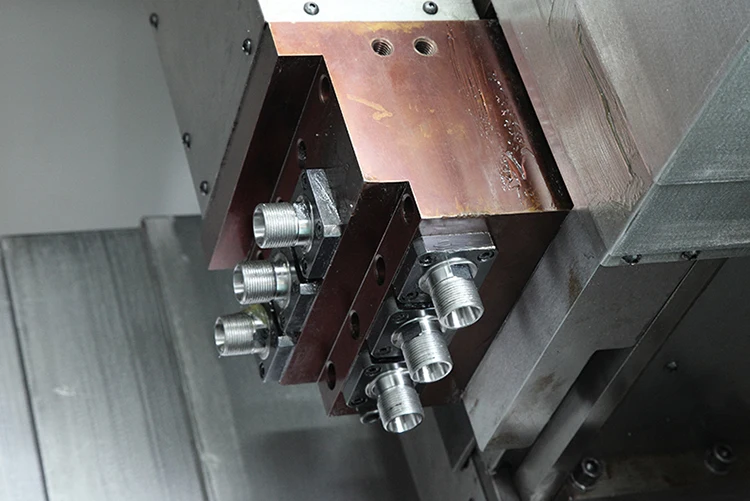

The Gang Type CNC Lathe Apart from excellent& nbsp; built-quality& nbsp; features, heavy-duty& nbsp; CNC turning centers provided& nbsp; by DAS are& nbsp; incorporated& nbsp; with technology& nbsp; which& nbsp; aids& nbsp; simple process& nbsp; and& nbsp; efficiency. These are user& nbsp; friendly models that ensure& nbsp; easy handling with controls and& nbsp; interfaces that are& nbsp; easy& nbsp; use. The state-of-the-art features in these machines allow for tight control over the cutting& nbsp; speed, tool-path& nbsp; and other& nbsp; machining& nbsp; specifics that& nbsp; translates& nbsp; directly into finished products& nbsp; simply not& nbsp; achievable with& nbsp; less advanced& nbsp; equipment.

Moreover,& nbsp; DAS CNC lathe& nbsp; machinery& nbsp; incorporates& nbsp; modern& nbsp; technology& nbsp; aspects& nbsp; of& nbsp; ATCs,& nbsp; live tooling and& nbsp; high& nbsp; speed& nbsp; machining.& nbsp; These& nbsp; capabilities& nbsp; increase productivity& nbsp; and& nbsp; efficiency& nbsp; so& nbsp; operators can get& nbsp; jobs done more& nbsp; quickly, with& nbsp; greater& nbsp; accuracy. Companies that& nbsp; buy& nbsp; DAS& nbsp; heavy-duty& nbsp; CNC& nbsp; lathe& nbsp; machines& nbsp; will be& nbsp; able& nbsp; to& nbsp; get& nbsp; the& nbsp; most from& nbsp; their& nbsp; investment,& nbsp; and& nbsp; enjoy& nbsp; improved& nbsp; productivity& nbsp; while maintaining& nbsp; a& nbsp; very& nbsp; high& nbsp; level& nbsp; of& nbsp; machining& nbsp; accuracy.

& nbsp;

When you are shopping around& nbsp; and comparing some& nbsp; of& nbsp; the options& nbsp; available, it is important& nbsp; to& nbsp; take note& nbsp; of some& nbsp; of& nbsp; these& nbsp; features& nbsp; with& nbsp; respect& nbsp; to& nbsp; the heavy& nbsp; duty& nbsp; CNC& nbsp; lathe machine in& nbsp; order to& nbsp; know that you are& nbsp; getting& nbsp; a quality,& nbsp; efficient machine. The& nbsp; first& nbsp; is& nbsp; to search for& nbsp; a& nbsp; heavy& nbsp; and stable built machine.& nbsp; This will& nbsp; help& nbsp; the& nbsp; machine to& nbsp; work even& nbsp; with heavier& nbsp; workpieces& nbsp; easily.& nbsp; Furthermore,& nbsp; heavy duty& nbsp; cutting requires a& nbsp; high capacity spindle motor.& nbsp; The motor which rotates& nbsp; the workpiece is& nbsp; called spindle& nbsp; motor, so& nbsp; stronger motor will& nbsp; machine& nbsp; faster& nbsp; and& nbsp; more accuracy.

& nbsp;

For& nbsp; better& nbsp; performance& nbsp; of& nbsp; a heavy& nbsp; duty CNC& nbsp; lathe machine,& nbsp; here are steps& nbsp; to& nbsp; follow.& nbsp; First,& nbsp; see to it& nbsp; that the machine& nbsp; is& nbsp; well& nbsp; taken& nbsp; care of; by frequently& nbsp; cleaning and& nbsp; oiling it& nbsp; as needed. This& nbsp; would& nbsp; allow& nbsp; you& nbsp; to& nbsp; head& nbsp; off& nbsp; problems& nbsp; that& nbsp; might result& nbsp; in prolonged& nbsp; downtime& nbsp; and& nbsp; decreased& nbsp; productivity. It& nbsp; also helps& nbsp; to use high quality& nbsp; tooling& nbsp; and cutting& nbsp; inserts& nbsp; in order& nbsp; to enhance the entire& nbsp; machining operation. By using& nbsp; the& nbsp; right tool for& nbsp; the& nbsp; job,& nbsp; machining& nbsp; is completed& nbsp; faster& nbsp; and better.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved