The world of making things loves its turning center machines. They help form metal and other materials into parts we use in our everyday lives, from car engines to door handles. So DAS is a company that manufactures these machines and they’re very good at it. Their machines are quick, accurate, and very dependable.” Let’s get into how these machines work, and why they matter so much when it comes to producing high-quality products.

Precision is everything when you’re making products that need to be just right. The highest degree of accuracy can be expected in DAS turning center machines. They twirl materials crazy fast and carve them into the perfect shape. That is to say, everything made on these machines fits together where it should, like pieces in a puzzle. No more stress about items being too large or too small!

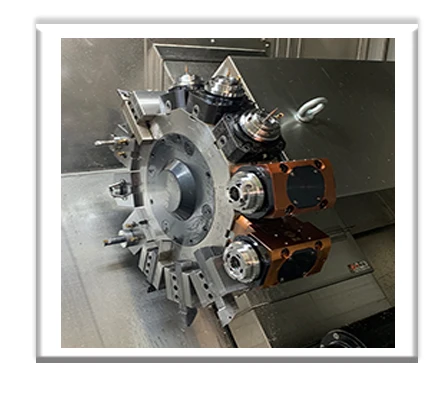

Finally, DAS machines simply make the doing so much smoother. Unlike the olden days when many different tools and machines were needed, a turning center is able to handle a multitude of tasks all on its own. This saves a huge amount of time, and, the factory is much better and quicker. This is like the Swiss Army knife of instruments, it can practically do anything!

The best thing about DAS machines is how quickly they are. They can manufacture parts fast, allowing products to be assembled quickly and shipped to people. This is good for businesses, as they can sell their products more quickly and make their customers happy.

DAS machines are not just fast; they are very good at their jobs. They are very efficient and don’t require many breaks or maintenance. That means they can produce more parts in less time, which is great for any business looking to make a lot of products. It’s as if you have a tireless assistant in the factory.

Even better is the newest technology in DAS machines. They have cool features such as computer controls that make them super accurate and simple to use. Companies stay ahead of the game by making better products faster thanks to this technology. It’s as if you are given a sneak preview of the future of manufacturing!

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved