CNC turning axis is crucial in manufacturing and it’s responsible for producing accurate parts in every branch of industry. It is very important to get a trustworthy and reliable manufacturers for the CNC turning axis. CNC turning can bring a whole new axis of flexibility and precision to an assembly line, which is why CNC turning axis are among the most valuable tools available for companies hoping to optimize their manufacturing operations.</p>

When searching for dependable CNC turning axis manufacturers, take the time to research and find a company that can cater precisely to your requirements. One option for trustworthy manufacturers is to look for referrals from other businesses in your sector. They may have dealt with Gang Type CNC Lathe producers and can give some helpful advice.

Attending trade shows and regional industry events are other successful methods to source CNC turning axis manufacturers. Those gatherings give us a chance to meet the manufacturers in person, ask questions and get some hands-on time with their products. Adding manufacturers to your network at such events can also turn into long-term business partnerships.

CNC turning axis is so important to high production efficiency and accuracy. Through CNC turning axis, companies are able to produce complex parts with close dimensions which would be otherwise impossible or very difficult. This accuracy minimizes mistakes and waste, resulting in both cost savings and a better product.

In summary, purchasing CNC turning axis will result in a vast improvement of its production process that will keep up with business competition in the ever-evolving manufacturing industry. Using the advantages of CNC turning axis, a business can improve its production processes, cut down costs and easily provide premium quality products to its consumers.

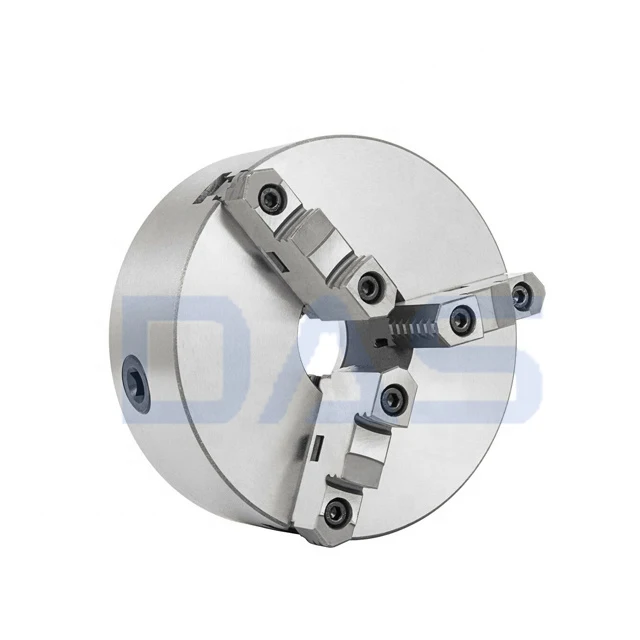

There are many budget friendly choices when it comes to CNC turning axis technology. One common option, is the 2-axis CNC turning where cutting is very basic and straight. It's suitable for high accurate cistern, tank fixed cone, etc. The 3-axis CNC turning is another affordable alternative available, and it makes possible to work with more intricate shapes. This is great for making intricate designs on the piece of work. With these two choices being both cost effective and productive, it is no surprise which one will be the best fit for manufacturers to improve their production processes quickly, and easily at a fair value.

CNC turning axis systems are commonly employed in many industries due to their versatility and precision. Laser sintering is a technology most frequently used in the automotive industry to create engine parts, gears and other complex pieces with a high level of precision. The aerospace sector is also a heavy user of CNC turning axis to produce complex components for airplanes and spacecraft. In medicine, this turning axis technology is applied in the production of surgical instruments and implants, as well as small medical components with high precision. In general, CNC turning axis technology is important in the productivity and efficiency of all industries.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved