High accuracy turning of metal parts

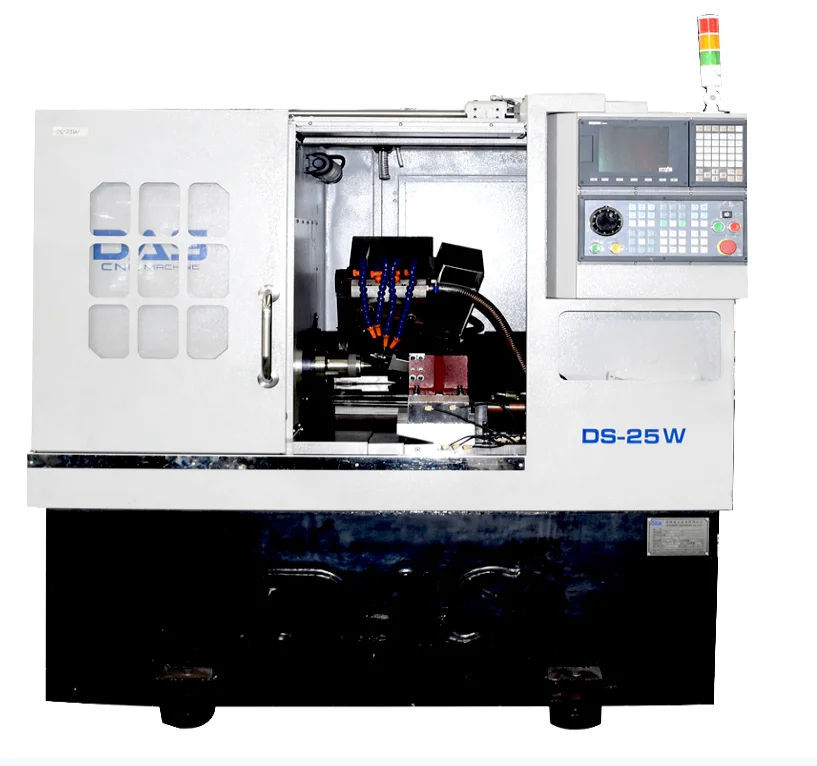

When looking to make a costly metal object with high accuracy, the axis is a significant concern in CNC turning machine. At DAS we can appreciate the critical need to attain the ideal size and surface finish for your manufactured products. Our CNC lathes feature multi-axis control capabilities with the capability to form complex and accurate shapes into multiple metal components. With our capabilities in precision machining, we can produce accurate parts to even the most exacting requirements.

Automation is critical to improve efficiency and productivity in manufacturing. CNC turning is a fast, accurate and efficient method of producing high quality parts quickly and allows us to save time in our own production process. Through the use of state-of-the-art robotics and CNC systems, we obtain an extraordinarily high degree of consistency and repeatability. Not only does this increase productivity, but it also ensures that we get our customers' orders out in a timely fashion.

One of the most important factors for achieving high machining accuracy is stable axis control. At DAS we have investment in some of the latest CNC driven turning machines, capable of very fast and controlled movements on several axis at the same time. That is how we are able to make intricate tolerances with our parts and not sacrifice quality. We are dedicated to providing you with a professional disclaimer system for secure axis control that makes us one of the most reliable suppliers of precision machining services in the industry.

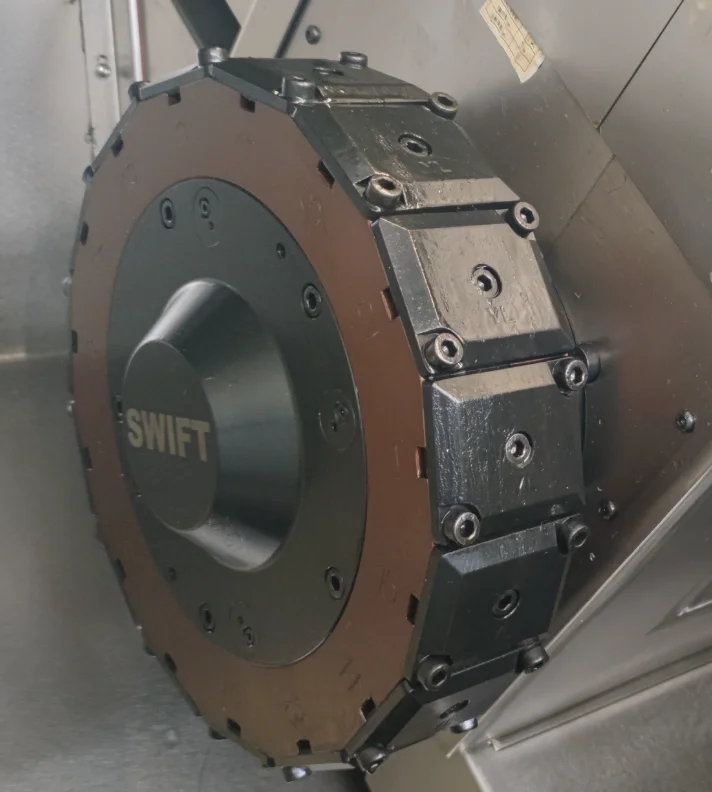

Keeping up with advancement in technology is necessary in the fast-paced field of manufacturing. At DAS, we use state-of-the-art tools and software to streamline our machining operations and enhance part quality. Our CNC turning centres are fitted with the most modern tooling technology to provide you with finish and tolerance you can rely on. This allows us to provide unrivaled quality to our clients by retaining a competitive edge through technology.

Although quality is our first consideration we realize that it is hard for the average person to spend too much. "We have worked hard to ensure our production processes are lean, driving good value for our customers but not cutting any corners on quality. Through application of lean manufacturing techniques and economies of scale, we can offer value engineering that fits within our customers budget. We always aim for value for money and we believe in being a low cost supplier.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved