Why Swiss Machining Centers Stand Out from the Rest in Manufacturing Here are some of the advantages offered by swiss machining centers that put them among favorites in manufacturing world. A major advantage lies in its ability to carry out several operations on a single machine set-up. That means parts can be quickly and precisely machined, minimizing (often eliminating) multiple machine changes and setups. In addition, Swiss machines are also known for their high degree of automation which leads to higher machine utilization and less labour costs. The accuracy and reliability of machining plays a role in the quality of parts generated, which means there are less defects to be found and customers tend to be happier.

In addition, Swiss machines are very flexible pieces of equipment to support complicated geometries and close tolerances with precision. What that means is that manufacturers can create parts of all types and sizes (within reason) with varied tolerances, so long as they are no larger around than its ability to do the job. It makes Swiss machining centers valuable tools in today's tightening marketplace. The flexibility to process a wide range of materials including metals, plastics and composites broaden the potential applications in multiple industries for these machines.

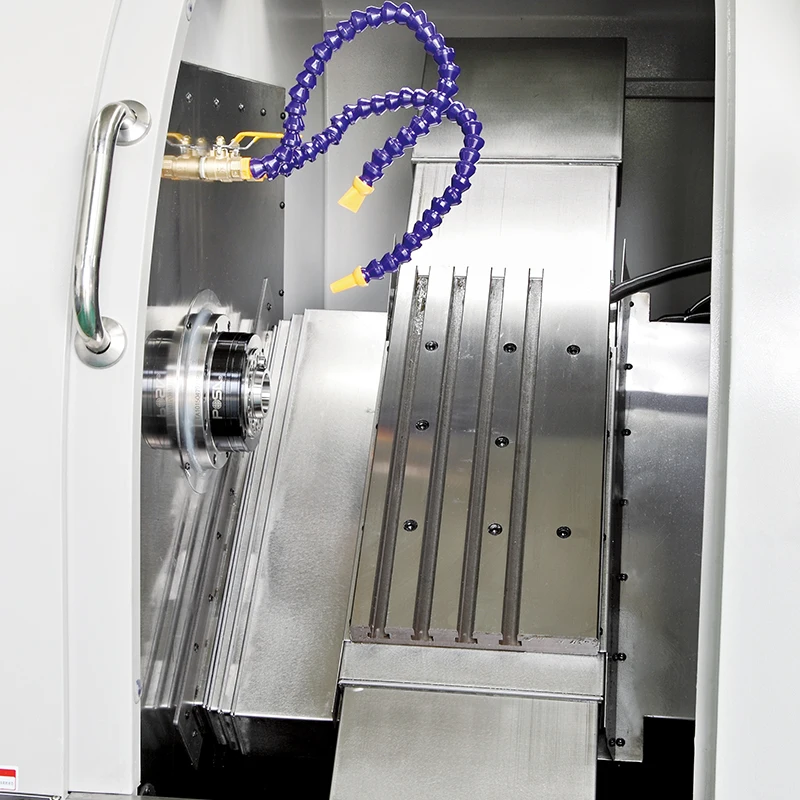

The high precision machining capability is one of the most important advantages of Swiss type machining centers. Such machines provide the precision necessary to maintain close and smooth tolerances in order to produce the parts which accurately meet customers' specifications. State-of-the-art cutting tools, high-speed spindles and advanced control systems enable Swiss turning centers to produce such fine measurements and surfaces even for the most complex and detailed parts.

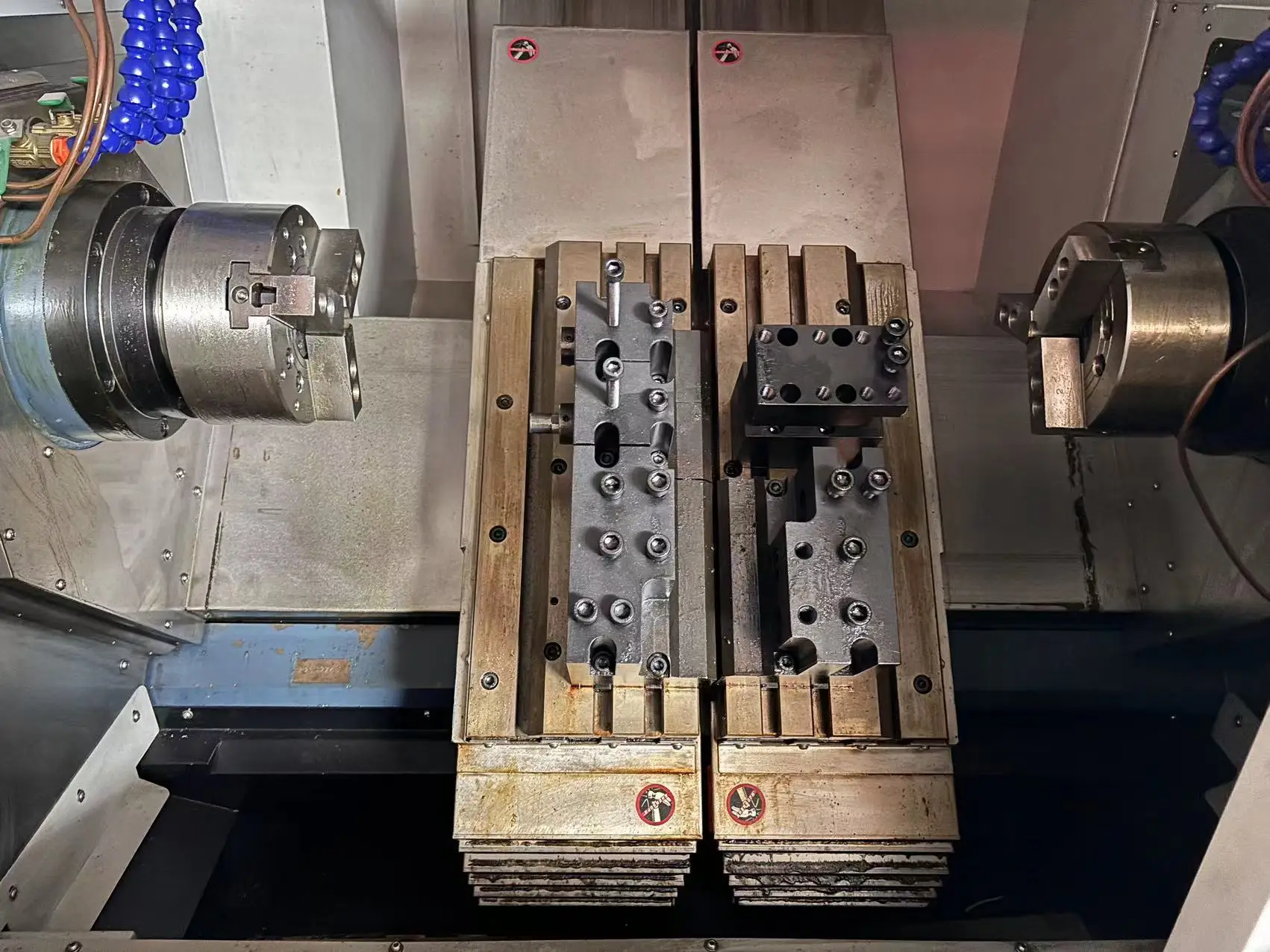

Also, Swiss machines feature cutting-edge technologies like live tooling and sub-spindles that make it possible to perform numerous machining operations on extremely small parts with high tolerances. These capabilities are of particular interest in applications where precision is key, namely aerospace, medical devices, and automotive. By arming themselves with Swiss machining centers capable of very high precision, manufacturers can then continue to meet the often extreme quality demands of their customers – increasing their competitive advantage in today’s increasingly crowded marketplace.

A Variety of Offered by Swiss Machining Centers There are so many benefits of Swiss type machining, with high precision cutting being one aspect that just makes them invaluable pieces of modern machinery. With the capability to complete multiple operations in a single setup, process complex form-geometry and hold tight tolerances, Swiss machining centers are key to producing parts fast and economically. To remain competitive and keep up with today’s market fast pace, manufacturers can count on the capabilities of high-end Swiss machining centers.

If you need the highest quality Swiss machining centers, there is no one better to turn to than DAS. This state-of-the-art machines are renowned for their accuracy and reliability, they are in high demand within industries that require parts of the highest quality. The Swiss machining process is common in applications where tight tolerances and complex geometries are necessary, such as medical, aerospace, and automotive applications.

Configurations and Setup One of the typical problems some people experience with Swiss type machines, is programming and setting up. These machines are very advanced and need a hand of experts to program and use them accordingly. Since a reliable functioning and best efficiency can only be guaranteed by experience and professionally trained personnel. Furthermore, maintenance and calibration is needed to keep the machines in good shape and the parts coming out as desired.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved