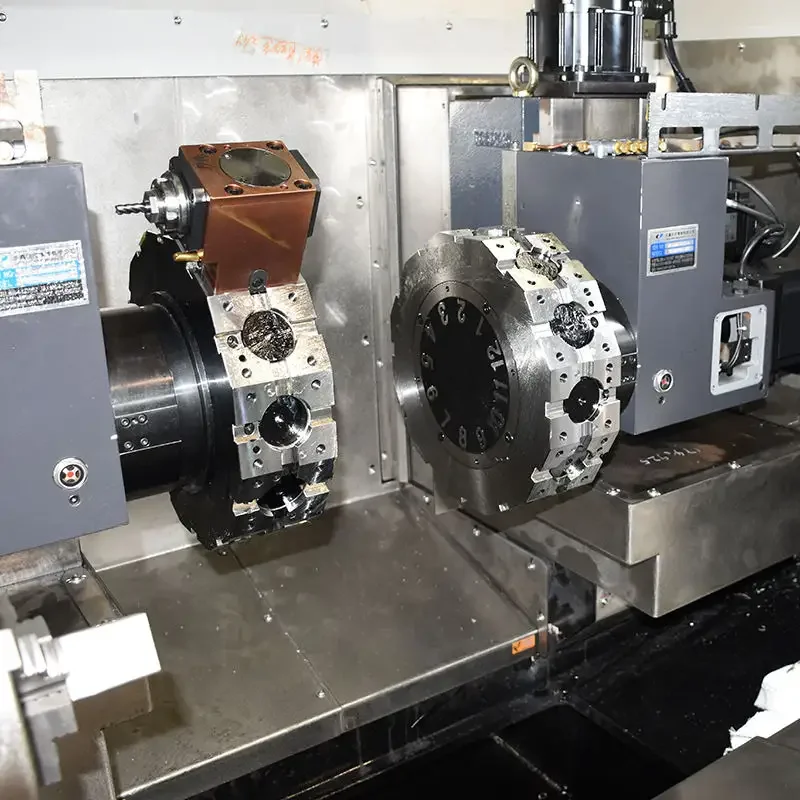

Horizontal CNC mills are a type of machine that cuts metal and other materials using a cutting spindle that holds a cutting tool and moves along 5 axes to perform the cuts. They function by pressing a tool horizontally against the material to form the shape you desire. The horizontal machining center machines are used to make parts in industries such as cars, airplanes and machines. I have one made by a company called DAS and they concentrate on making their mills accurate, efficient and user friendly

Wholesale Purchase Price: Application This type spindle motor is High speed precision spindle motor for CNC machining center, air cooled / water cooled;it has4kw,3.0kw, 2.2kw,1.5kw and 1.2kw.

In the event that you are looking to buy a high accuracy horizontal CNC milling machine, then DAS is the best choices readily available to you. These systems have been designed to suit businesses that have process accuracy and control needs. Featuring quality components and advanced features, DAS’ full line of CNC mills will help you to leave no doubt about whether your parts meet design specifications. So they cnc lathe milling machine work great on jobs that are slim with detail say, making a specialized part for a watch or electronics

Industrial by Design Professional Grade Mill Finish 12'' Aluminum Lazy Susan Turntable Bearings - 2, 12" Inexpensive Commercial Grade for Large Lazy Susans Features Smooth Ball Bearing Rolling Action

For businesses that require top-of-the-line milling performance, DAS’s horizontal CNC mills are the right solution. Tough jobs that make cutting large pieces of metal or contouring complex designs a breeze for these machines. They cnc machine axis are going to last and will stand up to heavy use without failing. This translates to less downtime and more production time — and that’s crucial in factories and shops like these, where every minute counts.

DAS’s horizontal CNC milling solutions are not only high performing, but efficient and cost effective too. They consume less energy and cut materials more quickly, which can save money on electricity and on materials. And because they are so precise, there cnc mill axis is little waste from errors, lessening material costs. That makes DAS’s mills a savvy option for businesses in need of lower costs without a downward quality sacrifice.

The team at DAS is always hungry to improve their horizontal CNC mills. They employ the most recent technology to keep their machines as cutting-edge as they can be. This could be things like improved controls, faster motors, or more accurate cutting tools. All of this cnc lathe mill enhancement means DAS’s machines can handle more complex jobs and work with newer materials that other machines would have a hard time handling.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved