CNC mill axis technology is king when it comes to things that make things. It allows machines to cut and shape with astounding precision. At DAS, we use this technology to manufacture components for almost anything you can think of, such as vehicles and computers. Today I am going to answer how we at DAS are increasing the Prosperity of our CNC mill axis machining.

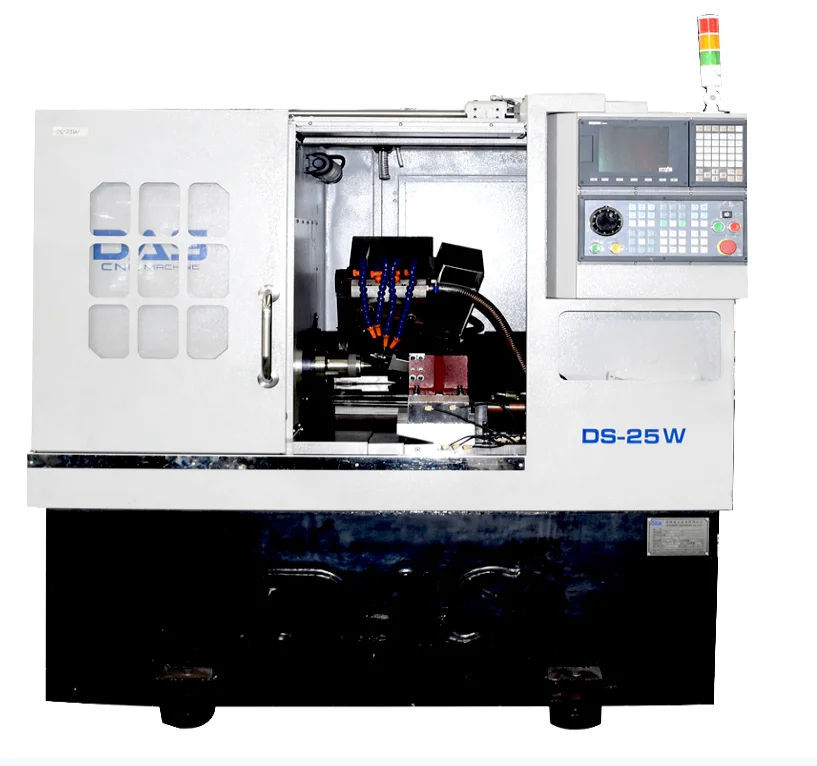

At DAS we know how critical it is for wholesalers to have perfect parts, every time. Our CNC mill axis machines are geared to this high standard. We have the world’s best tools for slicing metal and other substances into extremely precise shapes. That translates into less time cleaning up messes and more time selling perfect products.

This is something that actually helps us do our jobs more quickly and efficiently. For instance, the machines can be DAS programmed to perform the same cut repeatedly, without growing tired or making a mistake. This is super handy for larger projects that require many of the same parts.

Quality parts yield quality products. This is why DAS will only use the highest quality hardware in our cnc mill axis machines. This ensures everything runs smoothly and our customers receive what they need in a timely manner. Better parts equate to fewer breakdowns and more of that get-stuff-done feeling.

At DAS, we are always looking to improve things. We already use new ideas in our CNC mill axis machines to help us do it. These technological advances allow us to produce parts more quickly, with less waste. Doing more with less, we take that seriously here.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved