CNC mills are very precise instruments that work to shape metal and other materials super precisely. The machines employ computers to control the cutting tools, ensuring that each cut is precise. When you are working with these machines, the parts come out to perfectly fit each other well, no matter how tiny or complex their shapes. This kind of precision is difficult to achieve by hand or with simple machines. DAS produces high-precision CNC milling machines that are used in factories and workshops to produce parts which require close tolerances. Many sectors, such as car manufacturing, electronics and medical tools require this kind of painstaking effort. Without such machines, it would take longer and cost more to turn out detailed and dependable parts. It’s just nice to know that whatever you are making is going to work the first time, and not be an ever winding cat-and-mouse game of tweak-and-machine. That’s the power of high-precision CNC milling. For more advanced applications, you might also consider the 2024 High Precision Swiss Type 5 Axis CNC Milling Machine Lathe Hot Sell Metal Hardware High-Accuracy Manufacturing Plant Use.

This is why it is essential for wholesale buyers. Wholesale buyers need machines that work a lot but do not break and do not make mistakes. High precision CNC milling machines often fill that need. For example, when a buyer buys many machines to supply a factory, the tools must produce thousands of their parts at the same time. If the machines are not high precision, the parts will not fit or work properly. It is a waste of material and time. This is why DAS cares about quality and durability. Our machine is made from strong materials and designed cleverly, allowing it to work all day every day if possible. Wholesale buyers also want the ability to repair and maintain machines quickly. Everyone knows that downtime is lost money. This is why DAS provides easy-to-follow pocket guides and video calls for maintenance. Sometimes, buyers are afraid to buy high precision machines but DAS machines are worth their price. DAS machines save money in the long run because it helps eliminate mistakes and speed up production. Moreover, high precision CNC milling machines can work with many styles or materials. Buyers can use it in a variety of projects, and this is excellent, especially for businesses that are trying to grow and change. Overall, high precision DAS CNC milling machines help wholesale buyers achieve their goals quickly and easily.

Good machines are not always easy to find. The fact is that some sellers do promise a lot — and then deliver very little. DAS is remarkable in that it has machines built with care and tested prior to shipping. Buyers often find it difficult to believe suppliers which did not put clear information or does not own customer service. With DAS, buyers can know exactly what every machine is capable of and how it works. We also listen to questions and problems from the teachers, and we react,” she said. Occasionally, a buyer will shop online but become overwhelmed with too many options or vague descriptions. DAS provides transparent product pages and videos to inform buyers what they get. Another means would be to contract with factories or at trade shows in order to acquire reliable machines. DAS is actively involved in industry events so buyers can see the machines at work. That hands-on experience makes buyers feel secure about making a big purchase. Additionally, DAS can organize demonstrations or provide sample parts from our machines. This allows buyers to check quality for themselves. Wholesale buyers are also worried about shipping and delivery. DAS arranges packing and employs responsible carriers to ensure no damage. We also provide training for machine operators so that buyers can quickly get up and running with the machines.” Simply put, when you get wholesale high precision CNC milling machines through a firm like DAS, you can worry less and win bigger! What buyers get are machines that last, support when they need it, and a partner who gives a damn about their business. For clients interested in specialized turning solutions, DAS also offers the Swiss Type CNC Lathe with Double Spindle Swiss Type Machine.

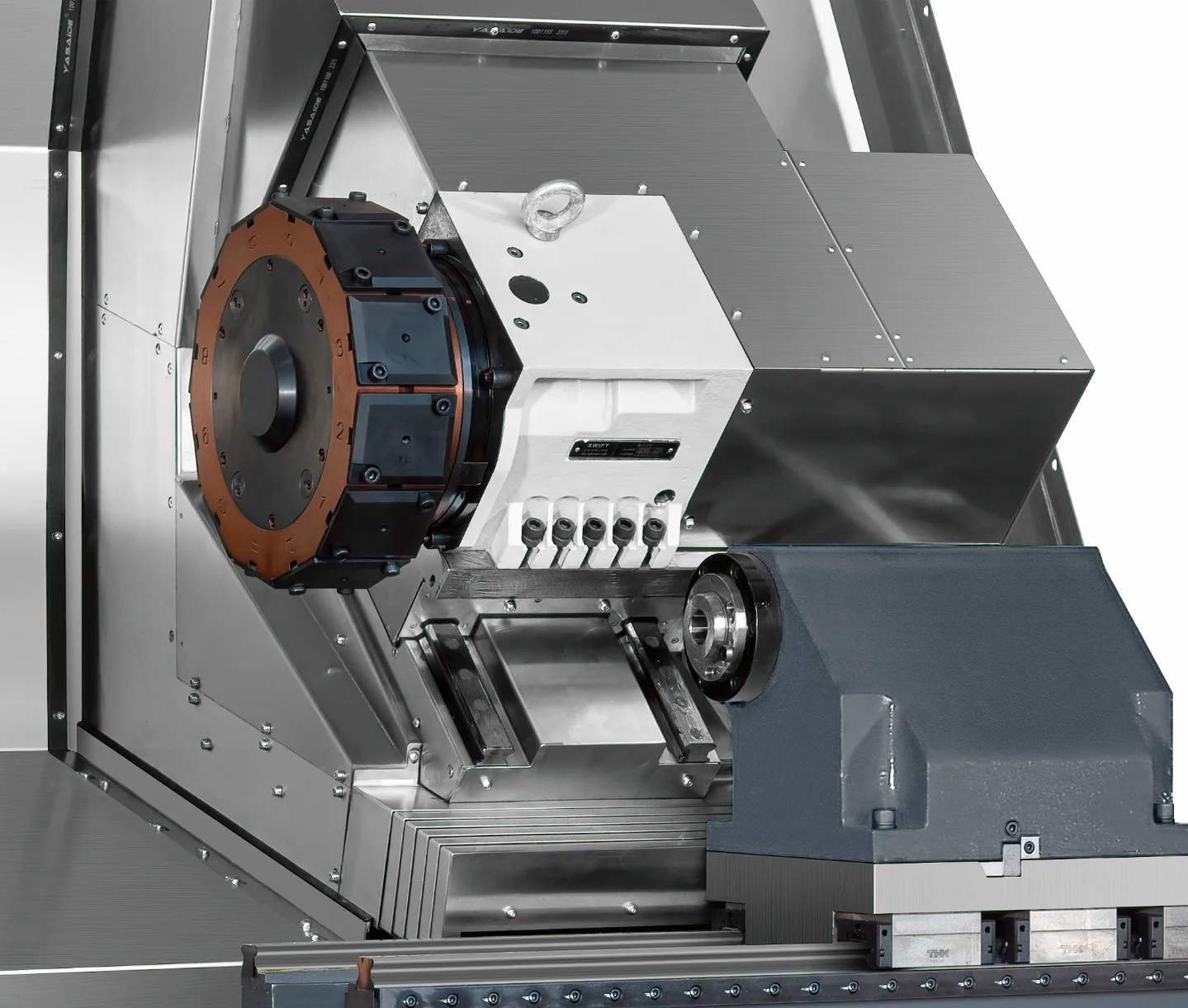

High precision CNC milling machines are special devices that can do very accurate cutting and shaping of various kinds of materials like metal and plastic. These machines are programmed to follow the instructions of a computer, and they are used to produce perfect parts that work great. When companies use high precision CNC milling machines such as those by DAS, they are able to create products that have a much higher level of quality and lifespan. This is because the machines can cut with minute measurements and repeat the same process many times without error. That means each part is just like all the others, which can be very important for things that need to be exactly the same — think car parts or medical tools.

In addition to making products better, they also help companies work faster. Since the machine operates by itself once it is programmed, it can produce many more parts in far less time than a person could do them by hand. This can save money, and allow companies to complete their orders faster. Precision CNC milling machines also reduce waste since they optimally use materials, cutting only what is needed, and when it is necessary. That is environmentally good and saves money on materials. In short, DAS high precision CNC milling machines enable businesses to produce good quality work with easy and without spending too much time, ultimately making both customers and companies happy. For companies requiring multifunctional equipment, DAS offers the Setting Password 5, Y Axis Turning and Milling Machine CNC Lathe With Automatic Loading Unloading Multifunctional CNC Lathe.

Another possible problem is errors in the computer program that tells the machine what to do. And if the program has an error, the machine can cut the wrong shape or size. But this can be avoided by simply reviewing the program before running. Some DAS machines also include user-friendly software that assists with error correction prior to cutting. The machine parts themselves may get dirty or wear out and the machine might not travel correctly some times. Keeping the machine clean and maintaining it regularly will keep the coffee flowing properly. If the machine makes unusual noises or shakes, it means a check-up is in order. Adhering to these tips can help ensure smooth operations and production processes of high precision CNC milling machines.

To get the best deal, companies should consider what size and features they need before making any purchases. Occasionally, paying for more features than you really need does nothing but cost extra money. DAS helps it’s customers determine which machine is the best for their needs and costs. It’s also clever to inquire about warranty and service plans because machines need a little TLC so they keep performing. DAS offers a range of service options to get companies up and running quickly when they have problems; it is also able to help keep machines executing without long stops.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved