The main shaft bearing and lead screw bearing adopt the structure of japan NSK and Sweden SKF, the first three and the second after P4, per stretching technology is adopted to ensure

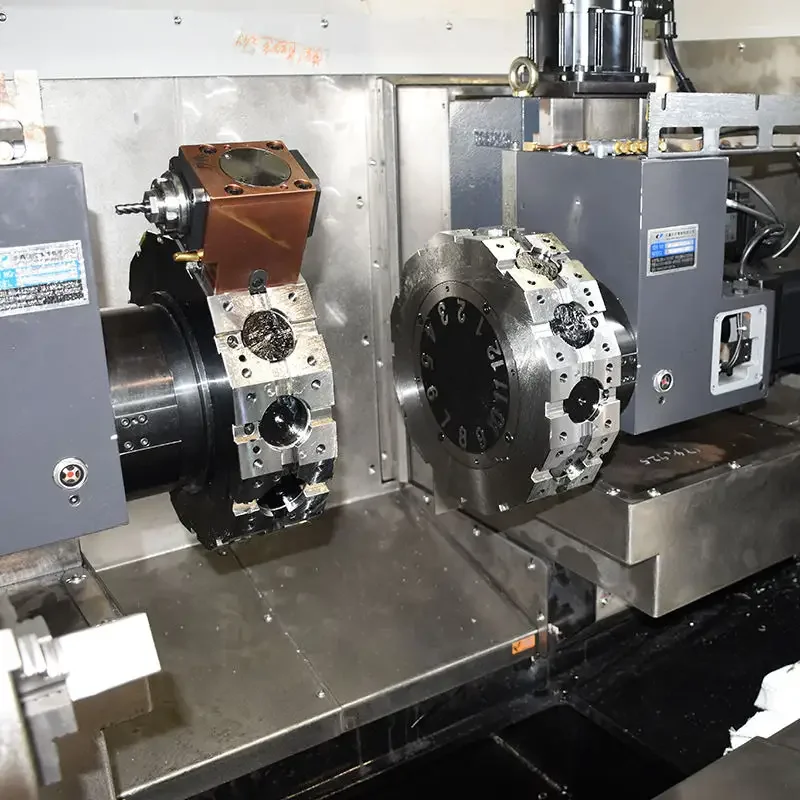

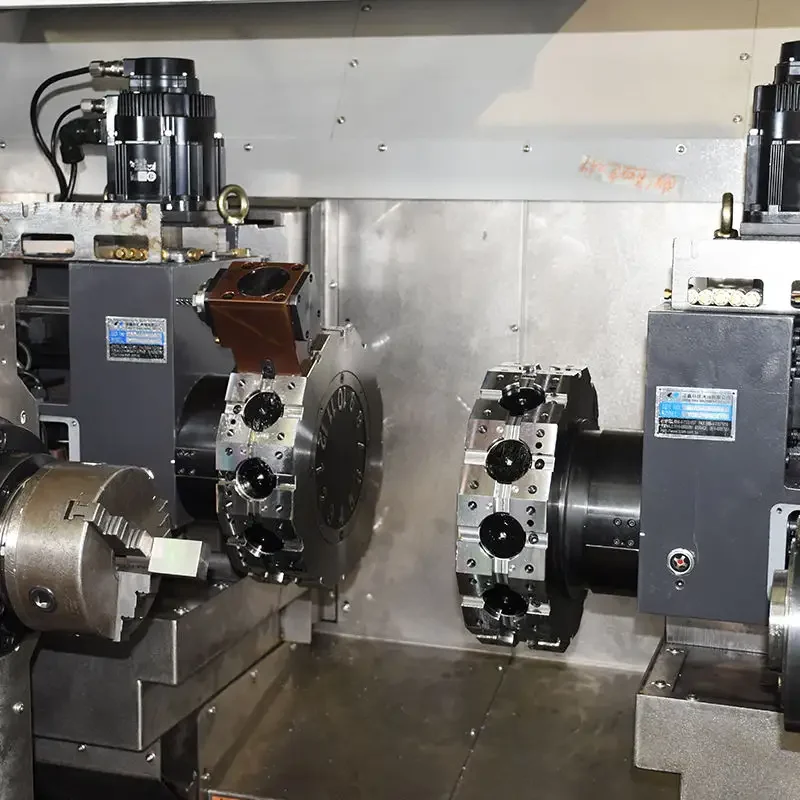

Double Spindle Double Channel Turning Milling CNC Lathe With BMT65 Live Turret Machine on Sale

- Overview

- Recommended Products

Introducing, the Double Spindle Double Channel Turning Milling CNC Lathe with BMT65 Live Turret Machine, now on sale from the trusted brand DAS. This cutting-edge machine is designed to revolutionize your machining operations with its advanced features and precision engineering.

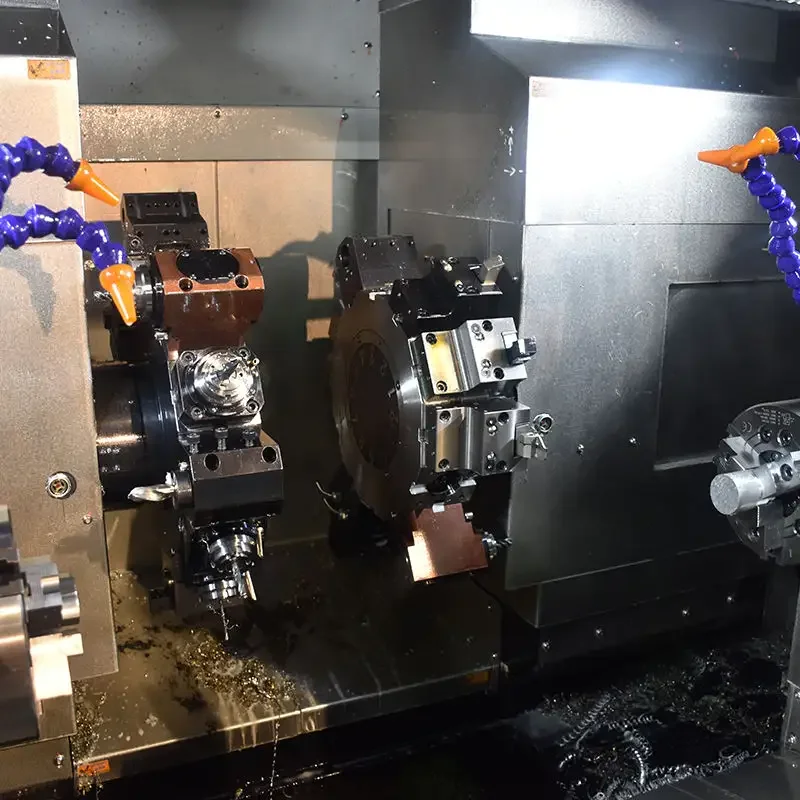

With two spindles and two channels, this CNC lathe allows for simultaneous machining on multiple workpieces, doubling your productivity and reducing production time. The BMT65 live turret further enhances efficiency by enabling quick tool changes and improved accuracy during turning and milling operations.

The DAS’s Double Spindle Double Channel Turning Milling CNC Lathe is equipped with a user-friendly interface that makes programming and operation simple and intuitive. Whether you are a seasoned machinist or new to CNC technology, this machine is designed to streamline your workflow and deliver exceptional results.

Precision is key in machining, and this lathe is built to deliver unmatched accuracy and consistency. The robust construction and high-quality components ensure stable performance, even under heavy workloads. Whether you are working on prototypes or high-volume production runs, this machine will meet your most demanding machining requirements.

In addition to its exceptional performance, the DAS’s Double Spindle Double Channel Turning Milling CNC Lathe is also designed for versatility. With a wide range of compatible tools and accessories, you can customize this machine to suit your specific machining needs. From intricate parts to large components, this lathe is capable of handling a variety of machining tasks with ease.

Don't miss out on this opportunity to enhance your machining capabilities with the DAS’s Double Spindle Double Channel Turning Milling CNC Lathe. Take advantage of our sale pricing and bring efficiency and precision to your workshop today. Invest in quality, invest in DAS

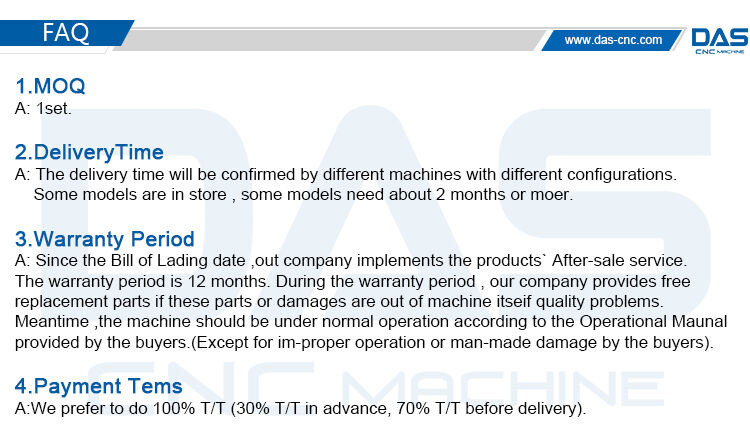

Unit |

TS-6-DIIY |

TS-8/10-DIIY |

||

Max. Swing Diameter |

φ210 |

φ300 |

||

Max. Turning length |

600 |

600 |

||

Max. turning diameter |

φ210 |

φ300 |

||

Spindle nose |

A2-5(46Type) |

A2-6/8(8/10inch) |

||

Sub-spindle nose |

A2-5(46Type) |

A2-6/8(8/10inch) |

||

Spindle speed |

0-4500(Factory setting) |

0-2500/1800(Factory setting) |

||

Spindle/ Sub-spindle bore |

φ56/φ56 |

φ62/φ62 / φ85/φ85 |

||

Spindle / Sub-spindle motor power |

11

Motorized Spindle

|

15

(Low speed high torque)

|

||

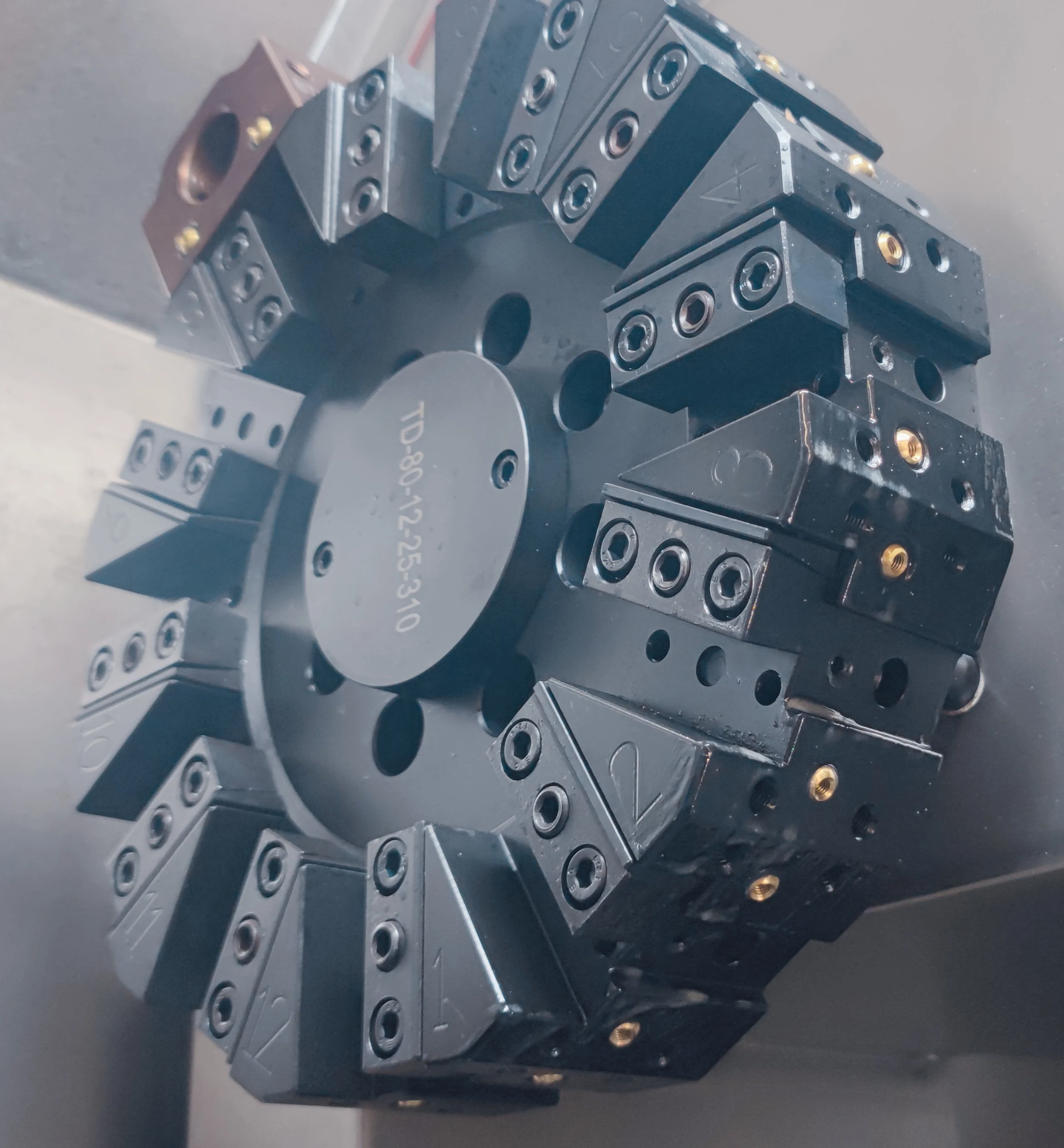

Tool installation |

BMT45 |

BMT65 |

||

Max. number of tools |

12 |

12 |

||

X1/Z1 axis travel |

500/370 |

500/450 |

||

X2/Z2 axis travel |

500/560 |

500/580 |

||

Y1/Y2 axis travel |

±50 |

±50 |

||

X1/Z1/Y1 axis servo motor power |

3.1/3.1/2.4 |

3.9/3.9/5.9 |

||

X2/Z2/Y2 axis servo motor power |

3.1/3.1/2.4 |

3.9/3.9/5.9 |

||

Guide form |

Linear guide way |

|||

X/Z/Y axis fast moving speed |

20/20/10(Factory setting) |

|||

Hydraulic Station motor power |

3.75 |

|||

Pump motor power |

750x2 |

|||

Net Weight |

5500 |

7600/7800 |

||

Machine Dimensions(LxWxH) |

3200×2000×1900 |

3800×2400×2000 |

||

Turret power motor power |

3.1/3.1(DIIP) |

3.1/3.1 5.5/5.5 - DIIP |

||

Turret servo motor |

0.75/0.75 |

|||

total power |

54(DIIP) |

75/82(DIIP) |

||

Bearing

The main shaft bearing and lead screw bearing adopt the structure of japan NSK and Sweden SKF, the first three and the second after P4, per stretching technology is adopted to ensure

ULTRA PRECISION THREE JAW CHUCK

High rigid cast iron casting, the workpiece is clamped firmly, and the service life is long. The hydraulic chuck can realize the automatic clamping of workpiece through the control panel, greatly saving the time required for manual clamping of workpiece and improving the processing efficiency

Numerical control system

Classic:knd1000t

Reinforcement:siemens/fanuc/mitsubishi/taiwan new generation

Linear motion guide

Taiwan yintai/hps grade p adopt taiwan track, higt rigidity, high precision, long life, strong dustproof

Ball screw

Taiwan yintai/h ps grade C screw rod Taiwan screw, as the core part of machine tool, is provided for general lead and large diameter ball screw better quality of work

Electrinic oil pump:centralized automatic forced lubrication. Each ball screw pair and each sliding guide surface are lubricated by quantitative pressure relief centralized by quantitative pressure relief centralized thin oil unit lubrication

Our major products include CNC series gang tool type lathes, turret lathes, take heart-type lathes and milling-type lathes, featuring space saving, low cost and diversified arrangement etc. They can also meet the demand for precise processing of different products. The products find widespread application in the manufacture of cars, motorcycles and accessories thereof, electronic industry, optical instruments, clocks and watches as well as special motors etc

We have precise lathe equipment, complete quality guarantee system, prompt goods supply as well as perfect after-sales service, which ensure us the first consideration when you purchase high-precision machine tools