At DAS we pride ourselves in our topnotch CNC Machine lathe products which are specifically engineered to meet the needs of our customers. Our machines are highly durable and deliver excellent performance in an array of industrial settings. We use only the finest materials in all of our products to guarantee durability and accuracy on every job. With DAS CNCs you can feel confident knowing that you’re investing in something reliable and effective that will get the job done.</p>

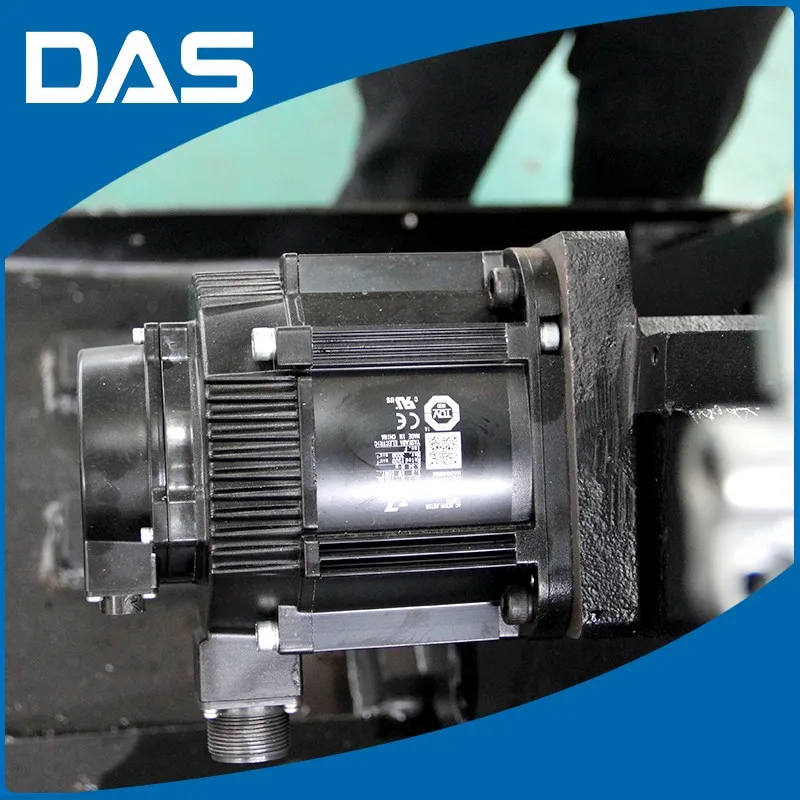

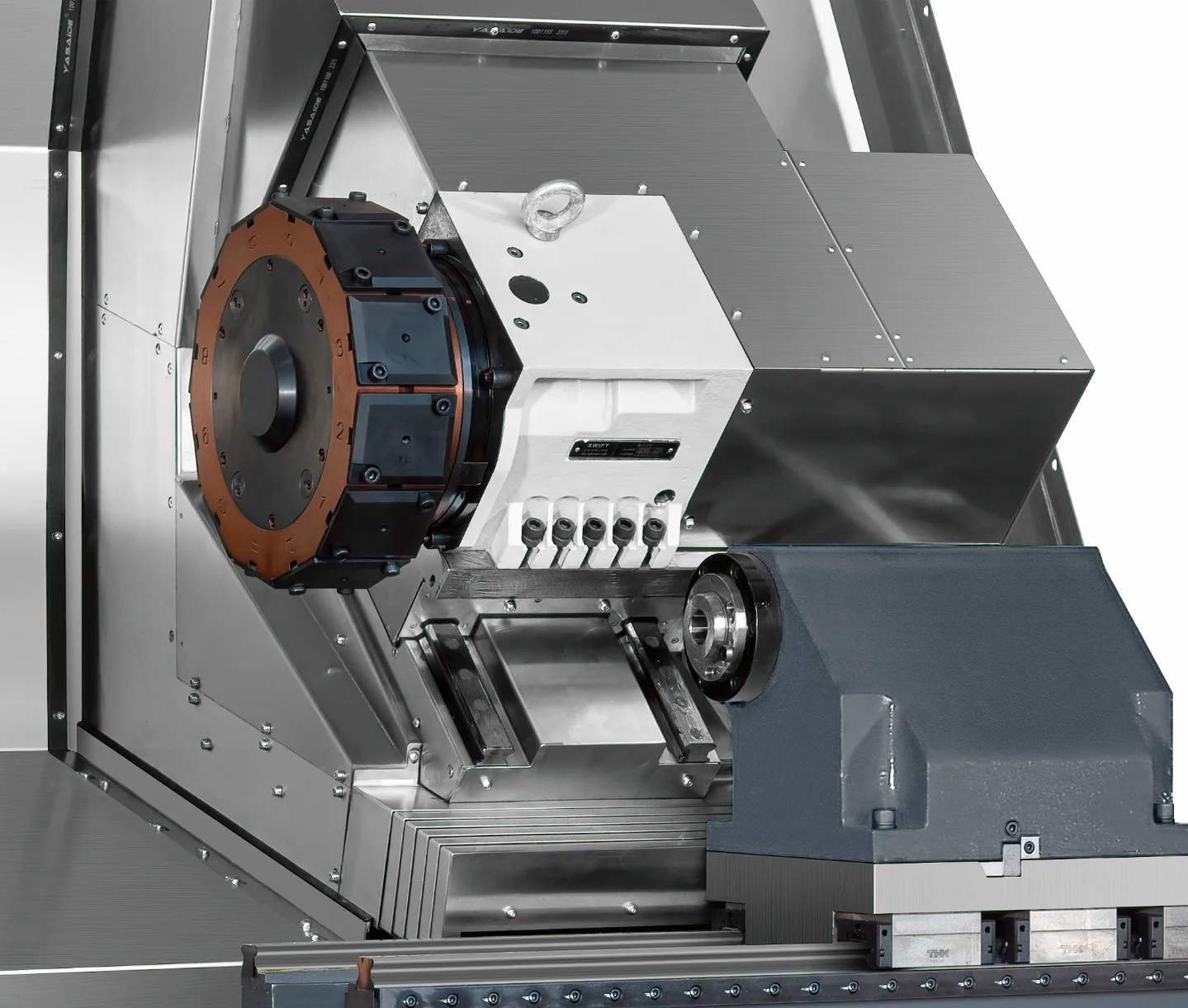

We only use the highest quality materials for our Gang Type CNC Lathe products. Each and every part from the frame to the cutting heads are hand-picked for optimal performance and durability. We carefully choose the best materials which will make our armored clothing strong, durable and resistant to everyday stress. It is this close attention to material and design, combined with attentive customer service that sets it apart from the competition and provides the sort of performance that will be closely scrutinized an eventually adopted by other manufacturers.</p>

At DAS we know the value of Price when making a cash purchase for industrial equipment. That's why we're happy to provide wholesale pricing on our CNC machine lathe products, so that you can have the tools you need without sacrificing quality or going over your budget. No matter if you're a little shop or an industrial facility, our discounted offers will help you get the best equipment while saving your budget. When it comes to DAS CNC machine lathes, you can have all the power and dependability that today’s industry demands at an incredibly affordable price.</p>

If you require a CNC machine lathe, there are several things which should be taken into account. The first consideration is the size of the machine. Be sure to select a lathe that is capable of turning the size material you will be working with. Also look at the horsepower of the motor. A higher-powered motor will enable you to cut through more resistant materials and bigger pieces. Another relevant issue is the number of axes of the machine. More axes mean more freedom and precision for your machining projects. Last but not least, think about the software provided by your machine. Ensure that it is easy to use, and has what you need for your fixed gear pipe maintenance gigs.</p>

There have been some interesting technological advances in CNC machine lathes lately. One of the most important changes is automation and AI. This enables the machine to think for itself with an increase in throughput and accuracy during machining. A further essential breakthrough is the use of sensors and monitoring systems for identifying and avoiding errors before they can occur. This saves time and money as well as the need to scrap the work. Another group of machines have added 3D printing to their capability list and opened up a whole new world of creative and exotic machined objects.</p>

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved