- Overview

- Recommended Products

Introducing, the all-new Torno CNC Madera Whirlwind Milling Machine by DAS. This revolutionary woodworking machine is designed for precision crafting and efficient production, making it the perfect choice for both amateur hobbyists and professional woodworkers.

With its advanced CNC technology, the Torno CNC Madera Whirlwind Milling Machine allows for precise and accurate cuts on various types of wood. Whether you're working on a small DIY project or a large-scale production run, this machine delivers exceptional results every time.

One of the standout features of this milling machine is its quick and easy setup. Thanks to its user-friendly interface and intuitive controls, you can get started on your woodworking projects in no time. The machine also comes with a built-in safety system to ensure smooth operation and prevent any accidents or mishaps.

The Torno CNC Madera Whirlwind Milling Machine is built to last, with a sturdy construction and high-quality components that can withstand heavy use and provide reliable performance for years to come. Its compact design makes it ideal for small workshops or home garages, while its powerful motor ensures fast and efficient milling of even the toughest woods.

This milling machine is also incredibly versatile, allowing you to create a wide range of products with precision and ease. From intricate carvings to simple cuts, the Torno CNC Madera Whirlwind Milling Machine can handle it all. Plus, with its affordable price tag, this machine offers great value for money compared to other similar models on the market.

Whether you're a seasoned woodworker looking to upgrade your equipment or a beginner just starting out, the Torno CNC Madera Whirlwind Milling Machine is the perfect choice for all your woodworking needs. Don't miss out on this hot sale and get yours today

Whirlwind milling cnc lathe features

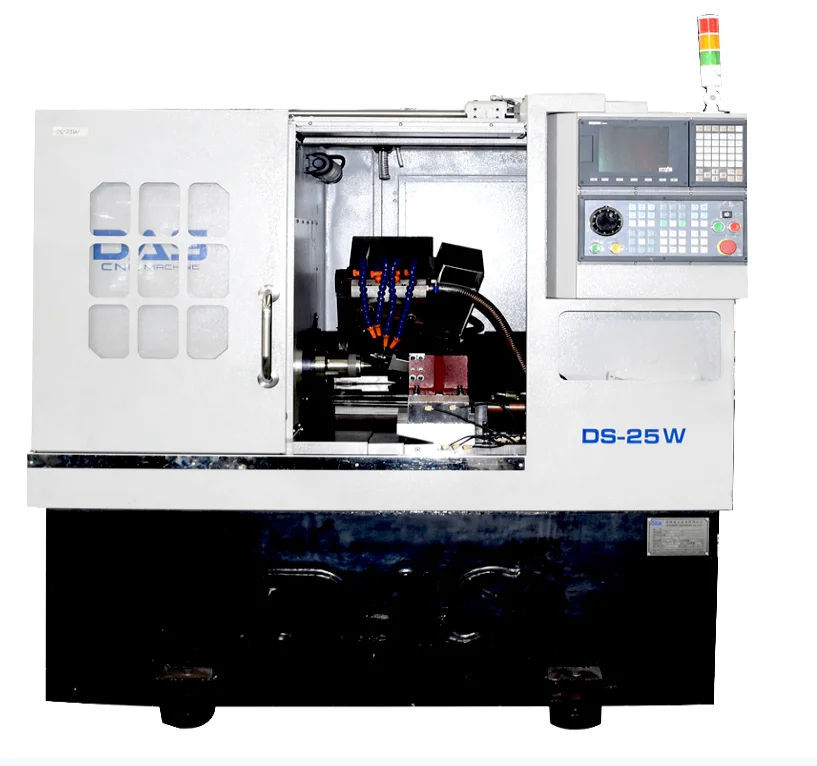

- Machine tool base is resin sand cast integrally, boasts high vibration resistance, small machine deformation

- Yaskawa servo drive is used for main shaft to ensure the high precision requirement of multiple thread screw

- The main shaft contains high precision Japan NSK precise bearing with the inner cone of main shaft directly mounted with elastic chuck in order to ensure the rotation precision

- Taiwan famous HIWIN / PMI high-precision Class P3 ball-bearing screw rod is used for the transmission portion of the machine tool

- The machine USES Taiwan SYNTEC system, Japan YASKAWA servo motor control

- Machine adopts roller guide rail structure, can withstand the larger cutting and resistance to impact

- The machine can be used for processing single head or multi-head worm

- Knife shaft can realize large Angle rotation

| Name - Parameter | DS-25W |

| Maximum processing length (mm) | 250 |

| Maximum processing modulus (M) | 1.5 |

| Maximum processing diameter (mm) | 20 |

| Tailstock function | No |

| With the knife guide sleeve | Have |

| Tool change style | Random |

| Spindle maximum speed (r/min) | 1500 |

| Spindle motor power (KW) | 4.4 |

| Maximum speed of the knife shaft (r/min) | 6000 |

| Knife shaft motor power (KW) | 1.8 |

| Tool form | Forming tool |

| Maximum installed quantity | 1 |

| Minimum system Resolution | 0.001 |

| X/Z Axis stroke (mm) | 100/250 |

| X/Z axis fast moving speed (m/min) | 12 |

| X/Z axis Repetitive positioning accuracy (mm) | ±0.003 |

| Taper (mm) | ≤0.005/100 |

| Card position size (mm) | ≤0.003 |

| X servo-motor (KW) | 1.3 |

| Z servo-motor (KW) | 1.3 |

| Hydraulic station (KW) | 0.75 |

| Water tank motor power (KW) | 0.12 |

| Cooling water tank capacity (L) | 100 |

| Power (kw) | 10 |

| Weight (KG) | 2300 |

| Size ( L*W*H mm) | 2100*1550*1800 |

Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. is located in Chencun, the important machinery town in Shunde District, Foshan. Sticking to the human-centering management, we are in possession of a group of highly competent technical personnel, a market oriented experienced sales team. In the gesture of sincere cooperation, we strive to establish a promise keeping and quality

Our major products include CNC series gang tool type lathes, turret lathes, take heart-type lathes and milling-type lathes, featuring space saving, low cost and diversified arrangement etc. They can also meet the demand for precise processing of different products. The products find widespread application in the manufacture of cars, motorcycles and accessories thereof, electronic industry, optical instruments, clocks and watches as well as special motors etc

We have precise lathe equipment, complete quality guarantee system, prompt goods supply as well as perfect after-sales service, which ensure us the first consideration when you purchase high-precision machine tools

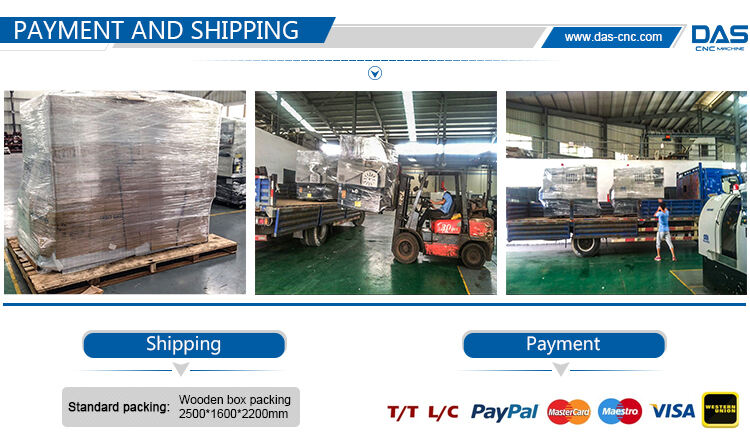

1. MOQ

A: 1set

2. DeliveryTime

A: The delivery time will be confirmed by different machines with different configurations. Some models are in store, some models need about 2 months or more

3. Warranty Period

A: Since the Bill of Lading date, out company implements the products after-sale service. The warranty period is 12 months. During the warranty period, our company provides free replacement parts if these parts or damages are out of machine itself quality problems. Meantime, the machine should be under normal operation according to the Operational Maunal provided by the buyers. Except for im-proper operation or man-made damage by the buyers

4. Payment Tems

A: We prefer to do 100% T/T