Swiss machining is an accurate and cost effective approach to producing parts and components. Other people learn machining which is highly technical and produces components at a high tolerance level. This technology is recognized for the creation of small changeable components and details with very precise demands on quality. Swiss machining offers wholesale buyers a cost effective solution that they are able to turn around quickly, which is why it has become increasingly popular in the industry.

Swiss machining offers wholesale buyers the benefit of producing parts with close tolerances above all else. This results that the final products are very precise and also uniform, which is particular important for applications in industries with needs of precision elements. Moreover, Swiss machining is especially useful for manufacturing tiny components in the hundreds of thousands, which can be quite cost-effective for wholesale. The whole prouction system makes set up fast and production efficient, assuring your orders to be finished on time. In addition, Swiss machining is suitable for a number of materials, including plastic and metal alternatives – giving you the opportunity to make even more wholesale decisions specific to your needs.

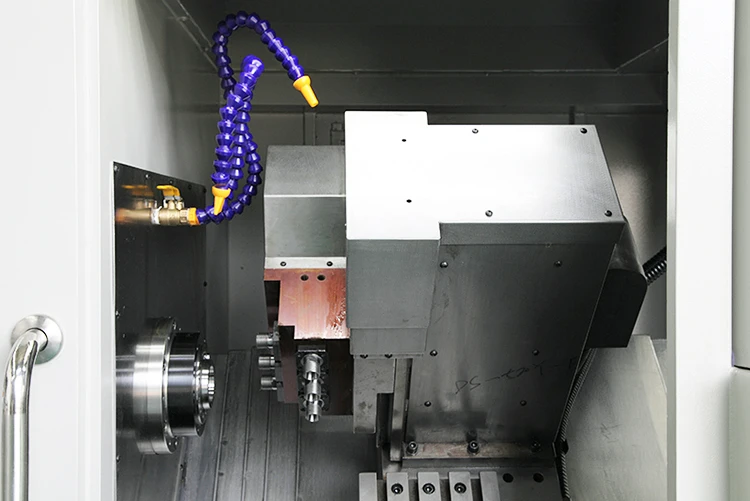

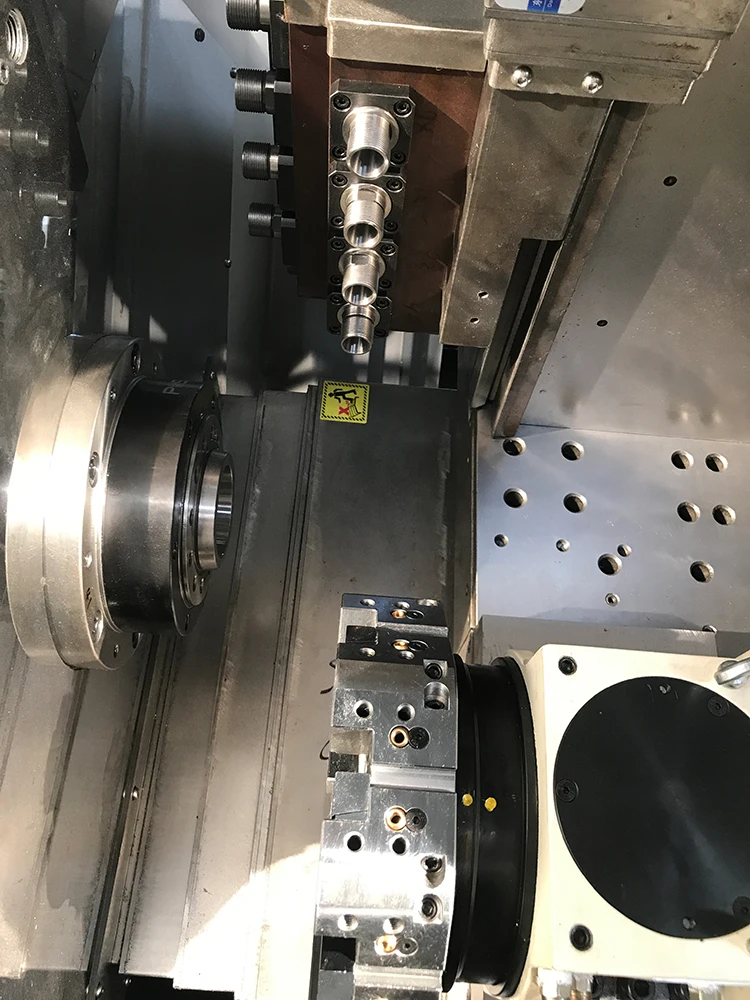

Swiss machining is different from other types of manufacturing, mostly in terms of the design and operation. Swiss machining differs from other methods in that it employs a sliding headstock and guide bushing which supports and guides the material up to the tool. This configuration achieves more precision and stability,and provides better finish. Also, Swiss machining is a multi-axis process that can perform several operations in one setup, eliminating the need for secondary handling and processing. This effectiveness not only accelerate the process but also reduces fehler in production. In fact, the advanced Swiss machining technology and specific features, Swiss type machines are suitable for industrial component manufacturing needed by wholesalers.

Swiss machining is the newest technology to change how the wholesale industry works, turning out precision parts quickly and accurately. DAS is a Swiss machining business for wholesale precision parts, with different services that will suit different businesses.

Easy access to DAS' Precision Swiss machining services where custom parts with a demanding level of detail can be produced that have tight tolerances. This accuracy allows us to manufacture premium parts that are precisely to the dimensions required by our customers. From our expert machinists who are trained to run Swiss machining machines at optimum efficiency to customer service that delivers the best quality part, we take pride in creating each piece with perfection.

Wholesale precision parts using Swiss machining can help take the complexity out of a manufacturer’s process and increase productivity across all production platforms. The precision and repeatability of Swiss machining minimize errors and self-corrections, speeding production time and cutting costs. The speed and adaptability of Swiss screw machines also make fast turn-around times possible, which in turn drives the ability for businesses to keep up with tight deadlines and customer demands.

Swiss machining is changing the wholesale industry like never before by providing a low-cost method to manufacture in quantity parts that maintain tight tolerances. Swiss machining is loved by businesses for its capability to produce high precision components with little waste and downtime. Thanks to DAS’ skill in precision Swiss machining for wholesale, companies can keep ahead of the game and provide better products to their customers.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved