High Accuracy Cutting with Excellent Manufacturing Efficiency

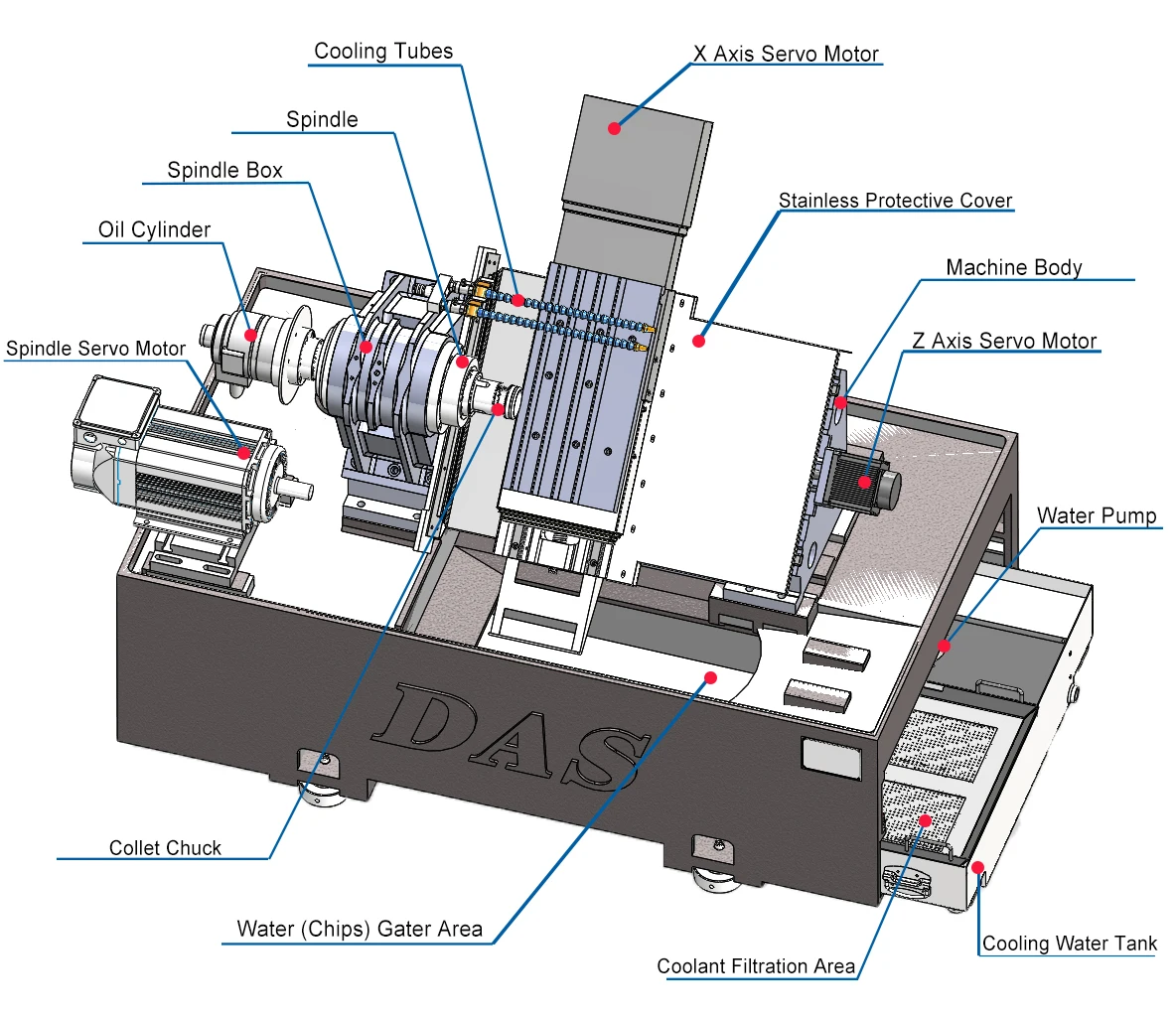

Precision is essential when it comes to manufacturing. We at DAS get it, and that’s why we value the high accuracy cutting abilities of our horizontal CNC machines. These computer controlled machines can be programmed to cut and form material with incredible accuracy to produce intricate parts. In addition, the greater manufacturing efficiency of these machines provides for quality levels that are uniform and also to high speed manufacturing capability to optimize production and improve plant productivity.

At DAS we are always trying to push the envelope of innovation with our horizontal CNC machines. These arcade games are designed with the latest technology that allows you to experience the increased productivity and improved performance. With advanced tooling options and the use of real-time monitoring systems, our CNC machines outperform the competition. This technological capability also serves to speed up the manufacturing process and increase the maximum performance of our machines above and beyond what today's industry requires.

At DAS, we build quality and durability into every horizontal CNC machine we fabricate. We value the solid delivery of units. Made from durable materials and crafted with care, these CNC machine tools have proven reliable even after decades of use. Guaranteeing longevity and consistently low operating costs, we know that our machines are ideal for you.Br Here at Colzer, we know our machines are so efficient they make the money back – saving cash for you year after year.

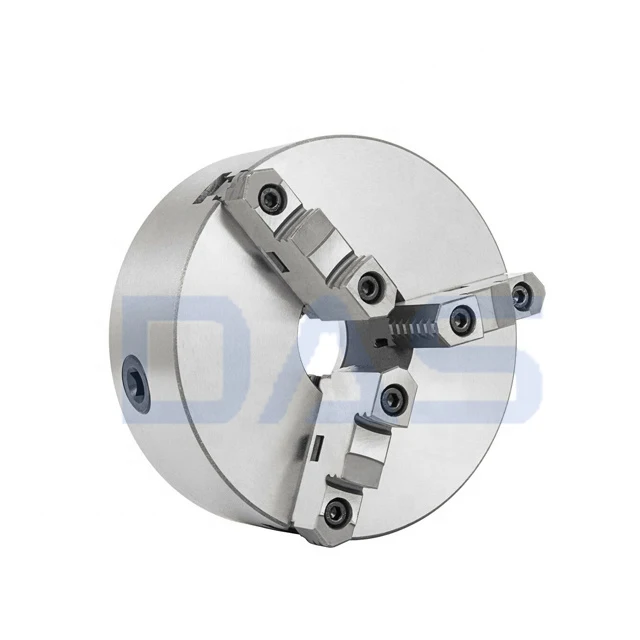

Customization One of the top benefits of DAS horizontal CNCs is the flexibility to tailor machining to specific needs. If that requires tweaking cut settings, choosing special tooling, or customizing workflow preferences, our machines allow for a great deal of customizing the process. That level of flexibility enables our customers to optimise their machining for the best possible results, specific for their needs. With DAS, you can tailor your CNC machine to reach peak machining effiiency and performance.

At DAS, we know that a smooth workflow and production are what enable you to make money. Our next-generation horizontal CNC machines improvethe efficiency of every stage of your production process. Tool change is automatic and all our machines interface with your other in-house manufacturing systems. This productivity gain translates into significantly reduced operating expenses and enhanced profitability for our clients. With DAS, you can produce more efficiently with better workflow and production.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved