A twin spindle Gang Type CNC Lathe is a highly efficient piece of equipment that is used in the industrial field to create parts at a much faster rate than what is possible manually while ensuring utmost precision. Our company, DAS, manufactures the finest twin spindle CNC lathes in the industry. These machines can do the jobs of two lathes at the same time, which makes it possible for factories to produce more goods more quickly.

Manfacturers get a tremendous speed boost with DAS twin spindle CNC lathes. These machines have a pair of spindles that can work on two parts at once. That's more doing and less waiting around. And because factories can use one machine to do more than one job, they might save space. This is huge for small shops that don’t have much space to spare.

Time is of the essence when it comes to manufacturing, and our twin spindle CNC lathes are designed and programmed to move. And because it can cut, drill and finish two pieces at a time, these lathes reduce the time it takes to produce parts. Factories produce twice as much in the same span of time as they used to. This is just right for companies that need to make a high volume of products fast to keep up with consumer demand.

DAS twin spindle CNC lathes aren't just fast, they are also very precise. These machines are designed to follow instructions to the word so that everything they make is a perfect copy of the design. This is really crucial for making parts that need to fit exactly, such as those on cars or planes. More precision leads to better products and happier customers.

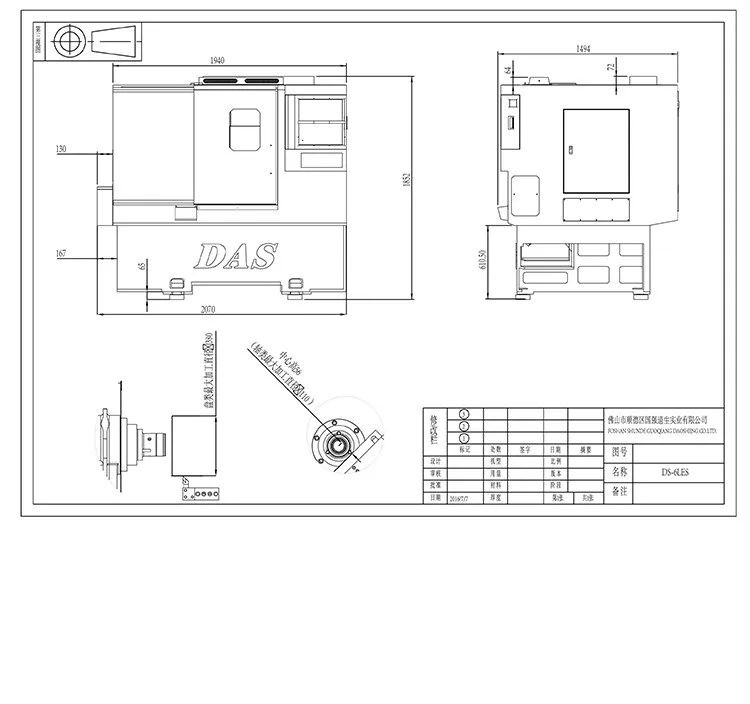

It is cutting kneading time and labor to knead..Order Information:.Our twin spindle cnc lathe for 2 kinds of products,two chaels..No master chuck required even for product change..Equipped with twin turning spindle..Cutting with continous-type carbide turning insert tool..Applicable for pitched threading..xECNC system equipped on the HA type for automatic chuck..hte turning unit and HA type are applicable for cross tapping and notching..Option:.Chip collector.Chips oil mist collector.LED Work light..Product range: 4-12mm.ID work range: 0.5-6mm.Spoon chuck holding work piece during working.Hydraulic chuck..The machine is equipped to hold down the workpiece while machining to ensure the highest degree of accuracy..Two NC Slides at Two Turrets with two trunnions structure and two main spinals..Does not need master chuck Both The finite rubber collet and chuck are not required..Control can be fitted to a conveyor belt (board) to ensure smooth processing..Can cut with a chisel when turning deep grooves..If it is equipped with multi-statin on driling side,the product in hexalobe form can be synchronized lathing.. rods (ychlate), use of piercing by the non-processed product, light work such as thin round bar can 2 months per hour..A long rod can also be used as a compromise chamfer..Can be mounted on two-hole work, nut machining, insert bolt machining, etc. are also available..If equipped with a front turning device and a back turning device simultaneously, the threading time can also be reduced effectively. Working with two parts at a time, these machines double production without requiring double space or operators. After all, DAS lathes are constructed to work hard and last long, so you’ll be spending less time repairing machines and more time making parts.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved