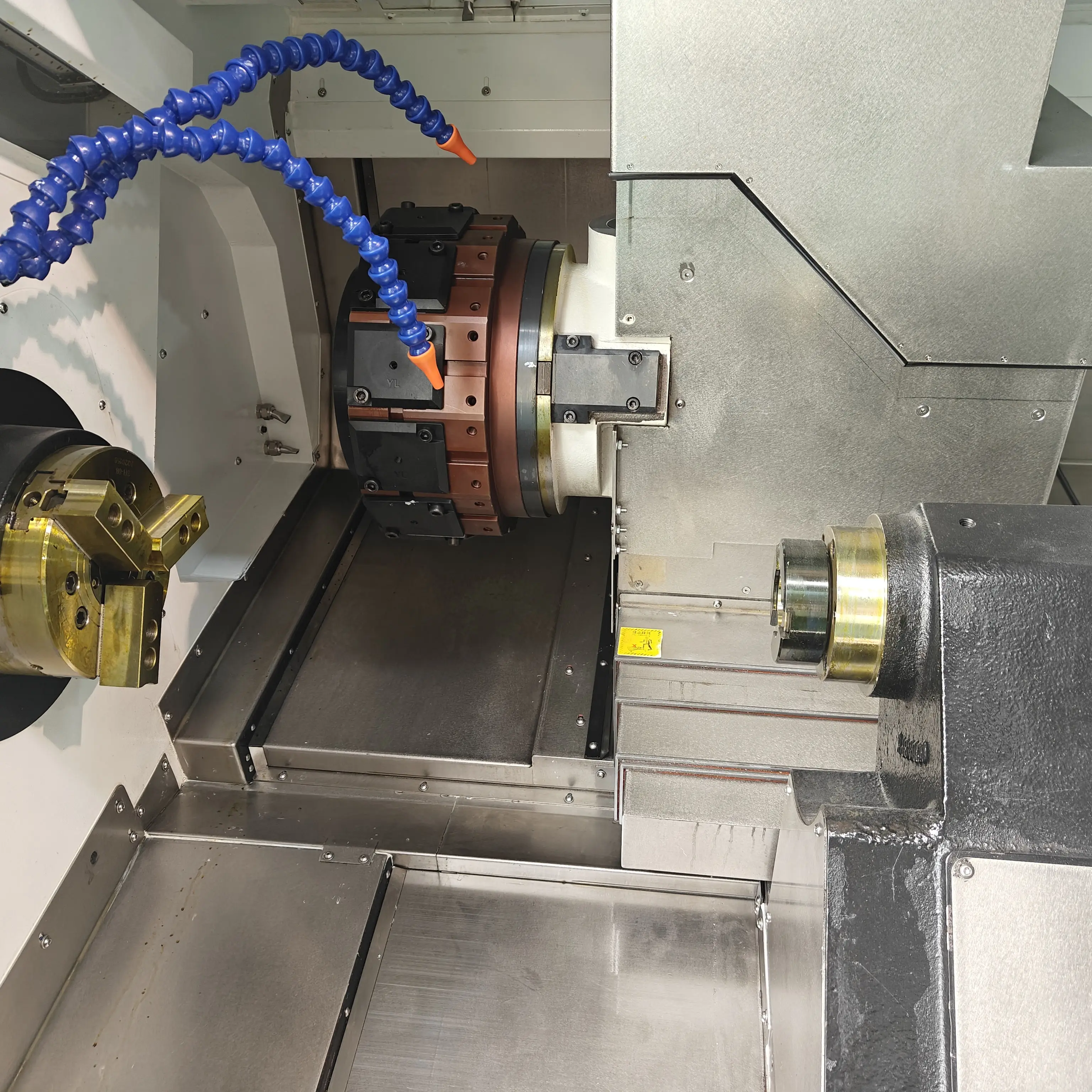

high quality horziontal turning centre for sale wholesalers.

When it comes to manufacturing in the industrial sector; a high quality turning center could be the difference between an entrepreneur who sinks and swims. At DAS we realize the value of quality equipment that can help you reduce production costs. Our high precision horizontal turning centers are crafted to provide machine shops with the ideal combination of capabilities and agility, without any loss in service value. With over 20 years of industry experience,we have honed our machines to provide optimum performance while maintaining production budget friendly for any business wanting to expand and improve.

Best Cyber Monday Horizontal Turning Center Deals and Sales

It can be hard to track down where you get the best deals on a horizontal turning center these days with all of the options that exist in the marketplace. DAS, however take pride in providing low costs but without the sacrifice of quality. Our dedication to making inexpensive options for wholesalers distinguishes us from other companies. No matter small or big factory, we have a solution ranging form uniform bis and overstock for all you horizontal turning center requirement. By focused on our client satisfaction and product’s innovation, we aim to bring value for our customer by cost saving solutions that ensure their operations are efficient and profitable. When you need a great deal on top horizontal turning centers of unsurpassed quality, there’s no place better to get it than DAS.

There are several things to think about when you’re trying to select the best horizontal turning center for your business. First, consider the size and weight capacity of the machine. Make sure it can also deal with the kind of materials and parts you want to work with. Also think about how fast and powerful the machine’s spindle is to make sure it can keep up with your output. It's crucial to check the machine for overall quality of construction and longevity so that you need not replace it in the years ahead. Finally, consider the level of overall automation and how technologically advanced the turning center is, since these factors have a large impact in productivity and efficiency.

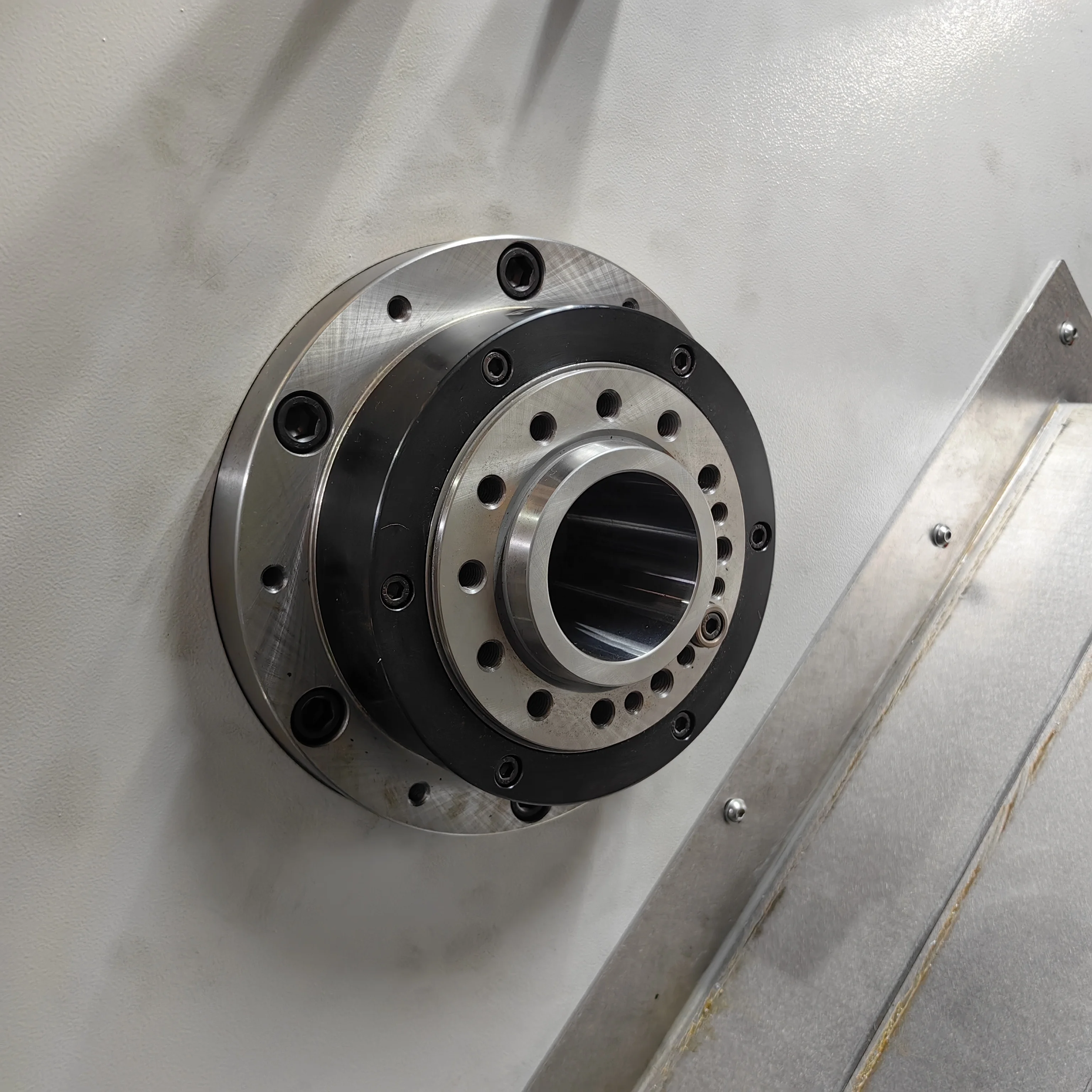

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Horizontal Turning Center: Typical Problems and How to Troubleshoot Them Here are some common problems that occur with horizontal turning centers along with tricks to help overcome these issues. One of the most prevalent problem is the tool wear that can result in low surface finish and impreciseness in dimensions. The problem: Inspect and replace damaged tools, and invest in long-lasting cutting tools. Chip control is also a problem that can damage the machine as well as part features. To avoid this, have adequate chip evacuation systems in place and maintain or clean your machine consistently to prevent buildup. Further, machining can produce vibration and chatter that affect surface finish quality and accuracy. One way to counter this is to make sure the machine is well set up, and incorporate vibration damping tools/strategies.

Productivity Accelerated by a Horizontal Turning Center To achieve the best productivity and profitability, it is important to increase productivity with a horizontal turning center. One method to increase productivity is by maximizing tool paths and cutting parameters in order to minimize cycle times and surface finishes. You can invest in automation solutions such as robot loading and unloading to make the production process more efficient and minimize downtime. Preventive machine maintenance and lubrication are also necessary for avoiding breakdowns and ensuring reliable operation. Finally, operator Training to effectively use the turning center can aid in productiveness and reducing errors. With the right machine, proper problem-solving and productivity-improving strategies, companies can maximize their horizontal turning center for greater success.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved