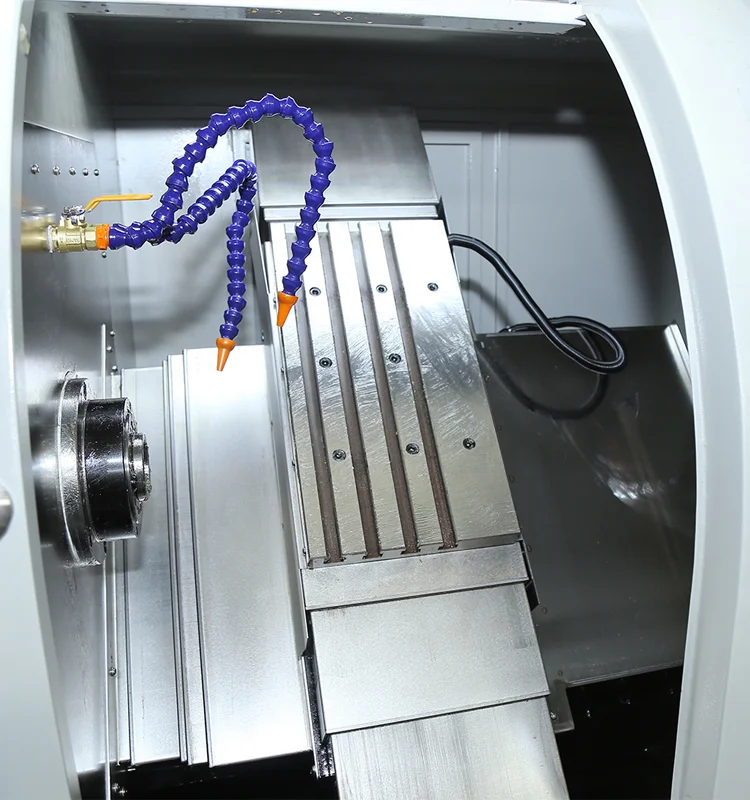

Horizontal CNC turning is a machining process that many different industries rely on to create parts that are incredibly precise. CNC is short for Computer Numerical Control, in which a computer is linked to the fabrication apparatus via CAD (Computer Aided Design) software, and converts the virtual design into numerical code. These figures are the co-ordinates of a plot and they dictate the path of the cutter. In horizontal CNC turning, the machine has the capability to operate from a horizontal positioning. This allows them to form metal or another material into specific parts by rotating it while different tools churn away at it. It is possible for our organisation (DAS) to use this technology to ensure that we only manufacture the best possible components for our clients. Gang Type CNC Lathe.

At DAS, precision is key. We have state-of-the-art horizontal CNC turning machines to ensure all parts we produce are immaculate. These machines allow us to make parts that are 100 percent identical to one another. This is really, really important in industries like aerospace and medical where the smallest error can make a very big difference.

For businesses that purchase in large volumes, DAS provides budget-friendly options that are still top quality products. Our horizontal CNC turning services are very efficient for high volume production. This allows us to charge lower prices because we produce lots of parts faster and with less material waste. Slant Bed Gang Type with Milling CNC Lathe.

DAS has set the standard by only utilizing the best in CNC technology. Our machines have self inspecting capabilities with checks to catch any possible errors or discrepancies. That means you can count on the parts you get from us to work as they should, delivering a more productive and efficient shop each and every day.

We get that time is money. Here at DAS, we are ready to serve your orders and never miss a deadline. Our services in CNC turning horizontal are dependable and fast, which is why we can provide you with a faster turnaround time on all orders than the competition. Which is exactly what we need sometimes (things always seem to need to have been done yesterday!).

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved