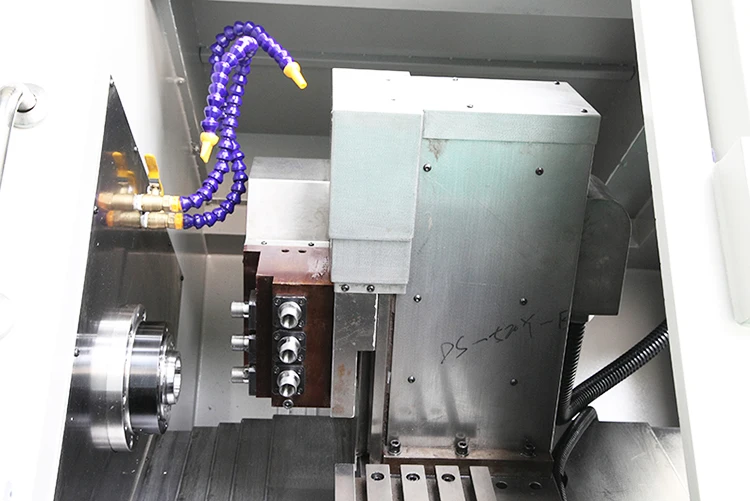

A critical part of the CNC milling machine is the spindle. It helps grip the tools that cut and shape the metal or other materials, as well as fits hands and spins it. If you are in the market for a CNC mill, the spindle is one of the most significant components you will need to consider. DAS has a range of spindles available to fulfill your specific application needs, whether you are looking for speed and precision or strength and durability.

The DAS spindles are meant to be spinning fast and hard. This also allows you to build parts faster and with fine detail. This is super useful, since it means you aren’t wasting time or materials. “This is all of a sudden so much easier, especially if you’re making an intricate part for a car or a plane — you want it to be just so. DAS spindles make it possible for you to do that with relative efficiency.

The spindles from DAS are also designed to be very tough and long lasting. They are not easily broken and keep working well day after day.” This is highly critical, as if a spindle breaks, it can shut down the entire operation until it’s repaired. Not so much with DAS spindles. They are designed to take abuse and keep ticking.

All work or projects may not be the same. Occasionally, you just need a spindle that can do a thing. DAS spindiles can be customized. That means you’re able to decide which features you require, so it fits your needs perfectly depending on what you’re making. That’s pretty cool because then it’s like you get your own tool!

With DAS spindles a cooling system is provided which would prevent them from becoming too hot. If a spindle gets too hot, it can be damaged. And the cooling system is meant to ensure that doesn’t occur. What this means is that your spindle will last longer and you don't have to replace it as often. It's almost like having a natural fan to keep everything at just the right temperature."

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved