DAS offers industry standard Swiss turn machining services to several industries. Our specialty in high-precision tools makes us stand out, in that ever component manufactured by us complies with the strictest standards in quality, precision and performance. Whether it's the medical field, aerospace industry, or anything in between Our pricing structures with quick lead times, along with meticulous and comprehensive quality control processes make us perfect for your Swiss turn requirements.

DAS is pleased to offer some of the best Swiss turn CNC capabilities in the industry. We have advanced manufacturing equipment, use fine process, and manufacture precision parts at the highest level. If you need precise geometries on your part, but are concerned about cost, take a look at KMC Stampings! We specialize in stamping complex, thin-gauge stainless steel, and our 3 7 axis screw machinesf can handle the most exacting applications. With attention to detail and a passion for perfection, we guarantee all of our parts are completed to this perfect standard.

When manufacturing parts for medical applications, accuracy and quality mean everything. At DAS, we have an expertise in the fabrication of Swiss turn parts, which meet the stringent requirements of the medical sector. Whether you are in the market for surgical tools like knifes and files or implantables, we can work with you to produce the components for the best performing and most reliable devices. We pride ourselves on the quality of our designs, and the attention we give to every last detail We manufacture everything to the highest tolerances – Not for the cheapest!

In today's competitive environment, time-to-market and lead times are critical. Quick Turn Swiss Turn Manufacturing DAS is well aware of the need for quick turn around times and we can offer fast lead times on your Swiss turn manufacturing. Our efficient production machines and processes enable us to provide faster turnaround times, without sacrificing quality. Whether you're working with tight deadlines or high-volume orders, we have the equipment and expertise to meet them, so you can keep your project on schedule and ahead of the pack.

At DAS, quality control is a top priority. We know that the longevity and performance of your parts are contingent on the quality of the machining. That's why we've put some tight, quality control standards in place for all the parts we produce to guarantee a quality that's above and beyond the rest. From our first look to final test, we take an all-inclusive approach to quality control to ensure each part is free from defects and meets your precise needs. By focusing on precision and our commitment to quality, we make sure to exceed your expectations and deliver parts that live up to our esteemed commitment to excellence.

In today's competitive market,Value for money is a must. At DAS, we provide affordable Swiss Turn Machining services to get the job done at a fraction of the cost whilst maintaining high quality. Combine this experience and knowledge with our efficiency, economies of scale, and our inventive mentality, we are able to tailor our processes suitable for producing high quality components es at prices lower than our competitors. Whatever be your needs regarding cost reduction in production or improvement in ROI, we wotk in close cooperation with your team to offer cost effective solutions tailored to suit your financial goals. We focus on the best possible value and the most competitive pricing we want to be your partner for your Swiss turn machining needs.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

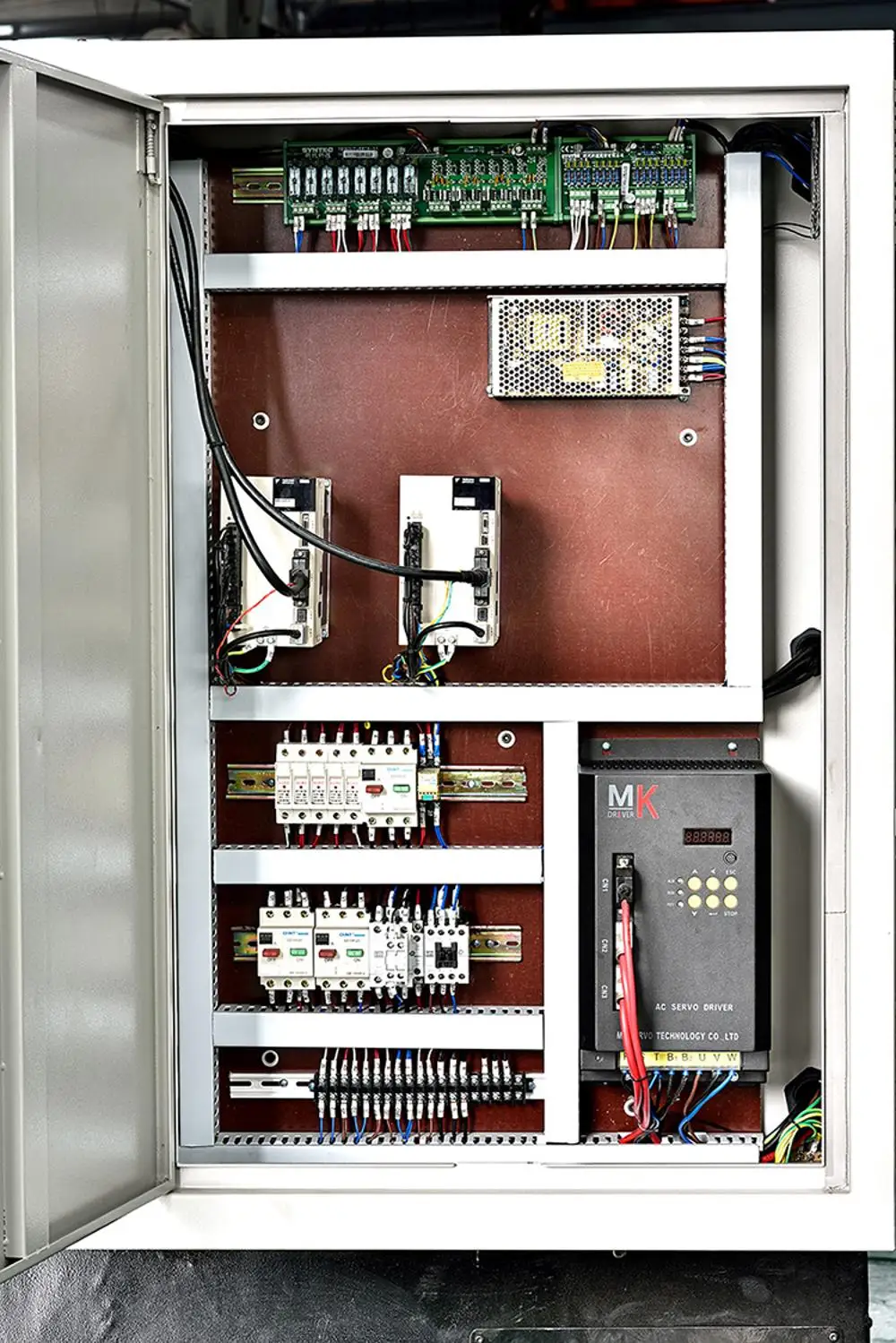

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved