When it comes to commercial work, in accuracy can mean all the difference in the world. As an industry professional, you no doubt take keeping up to date on the latest developments seriously and making use of modern technology to help drive your business. A technology that has changed face of the metal fabrication is the CNC turret punch press. DAS as one of the most advanced fabrication solutions provider, the CNC turret press machines that can elevate your production to new heights. Let's talk about the benefits of updating to a CNC turret press for your business.

No more manual punching and cutting, which can lead to errors and non-uniformity. Increase the Efficiency and Accuracy of Your Metal Fabrication Work You can improve the quality of your products and the productivity of your operation with CNC turret machines from DAS. These sophisticated machines have computerized operating systems that regulate for consistent accuracy with little human intervention. That means less errors, faster up times and better products. With CNC turret technology, you can simplify your process and concentrate on producing the best results possible for your customers.

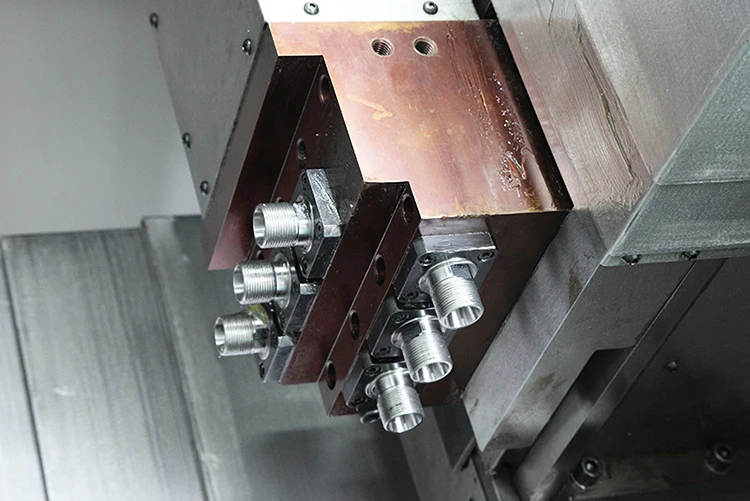

Productivity is of the essence, particularly when working with tight deadlines and during runs of high volumes of production. CNC turret punching maintained by DAS suffers from no such reliability issues: with these tools, you can increase your productivity and reduce costs without compromising precision. The processes that can be performed with these tools range from the simple hole punch to the more complex forming operation, and are carried out quickly and accurately. Comparable to automatic tool changing and & material handling features below, to fine tune their productivity feature CNC Turret machines to fall within ranges of impressive productivity. Eliminate bottlenecks and waste – with the CNC turret technology you are never limited by what you can achieve.

In the modern world, it is vital to customize yourself so you stand up in the crowd while fulfilling the specific requirements of your clients. By integrating DAS with CNC turret punching services, we can provide you with the ability to easily put your creative ideas to the test. Whether you want elaborate patterns, custom shapes, or precise cut-outs, our state-of-the-art machines have you covered. Using CNC turret technology means you can also work with smaller runs and offer custom solutions to customers, tackling new projects with security. Prototypes to full-blown productions, DAS has you covered with custom metal fabrication services that separate you from the pack.

Quality as well as cost-effectiveness play a vital role in the success or failure of a manufacturing business. Why compromise, when you get both with DAS CNC turret technology. Our state-of-the-art equipment is built to accomplish the highest quality results; consistently producing a product that meets the same high standards time after time. Moreover, when you streamline your production process with CNC turret technology, you can cut down on waste, avoid downtime and will save money in the long term. The payback of the initial investment for converting to CNC turret machines is quick not only because it enables you to be more competitive with your pricing, but also because it makes you a more competitive fabricator who people want to do business with.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved