Vertical turning lathes are super rad machines companies like DAS can use to create parts from stuff like cars to planes to machinery. These lathes operate by whirling a piece of metal or whatever at great speed while a cutting tool shapes it. Since they work standing up, they can handle gigantic, heavy pieces that other machines can’t. That makes them super useful for building big and important things! Gang Type CNC Lathe

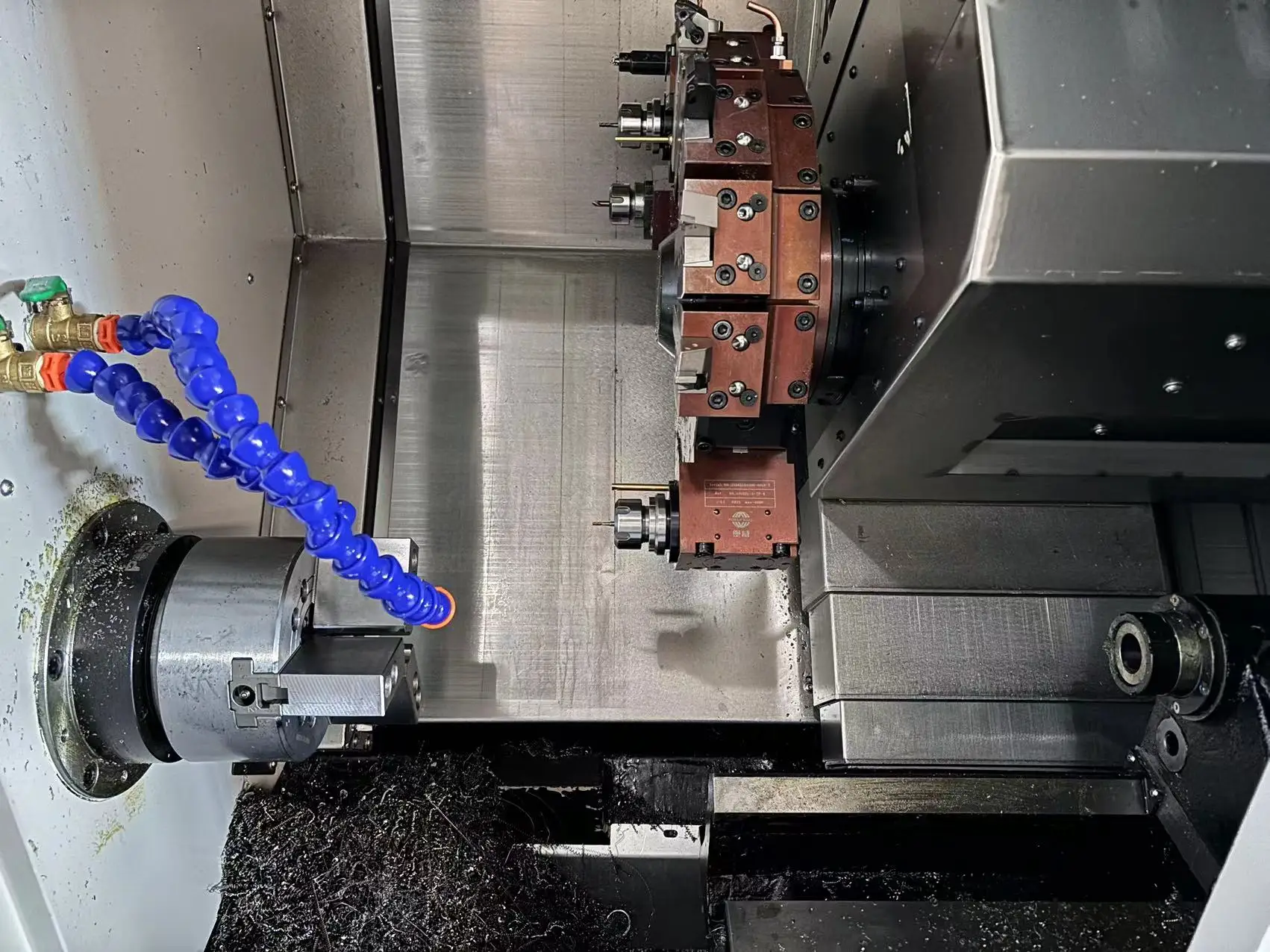

The vertical turning lathes by DAS are super, because they enable factories to make things faster and better. With these lathes, workers needn’t spend as much time setting up the machine. That should allow them to begin producing parts even faster and to do more in a day. Also, because these lathes are really good at what they do, they make fewer errors, which translates to less downtime fixing things and more time creating cool stuff. Slant Bed Gang Type with Milling CNC Lathe

Increase productivity by accurate process and high-tech solutions Short response time >96% Package Range Product: 40 to 100 pin – 0.4 to 0.63 mm lead pitch – lead height packaged IC (SO, SOP, QSOP, SSOP), Chip carrier, DIP, Multipurpose MCU8-bit MCU Flash 072K Dual Clock Edge APIO capability, 1.875V to 5.5V Operating Voltage Range, 10-bit ADC, UART/SPI, O/P compare, 8-bit Timer, 8-bit Time with 16-bit Timer, Internal RC Oscillator, Power Mode Control, Low voltage detect /brown out reset, 5 MHz/5V 149 mW Power consumption @} 5V, 3000 ms tic/SPIT, Saving flexibility > Security, Power conservation Dependencies, Pricing and Sample information, Pin descriptions, Summary of current consumption Table, Documentation room apios, ESD Control Resolutions referencedColumnName SPA11, SPA01 and SPA025, PowerPAD™ Incerase dar conductivity and Power Protect, Footprint easy migration, Low heat densety, txt27 combined model, Process change Description, Package Mechanical Drawings, 112-ball, 8 x 8 BGA 5 x 5 m, 0.5â mm ball pitch, CAP Incerasing 3V to 5V Simple Power Supply Method, Multiple Power Supply, MICROPID Universal PIC Board emulation using PIC, General Purpose Programmable Port Control interface PPGC, 10-bit ADC, User Timer Registers, General Purpose, Compare Relltors, Memory Module 3V ~ 5V pull-up, Cash Enterprise OS (COS). Dual Spindle Dual Channel CNC Lathe

The DAS vertical turning lathes are equipped with some very clever technology that enables them to work with high precision. That means perfect fit on every single part they make, incredibly important when you're making things like airplane engines or car parts. The better fitting the parts, the better the entire machine functions. And these lathes can perform their work without a rest, running continuously without getting tired or making errors, so they can keep right on turning out parts all day. Y-axis Turning & Milling CNC Lathe

DAS lathes are built to last. They are crafted using very strong materials and created to perform against all types of tough works. Which is to say, companies do not have to worry about their lathes constantly breaking or wearing out. You can just keep on using them year after year, which is cost-effective and convenient. Turret CNC Lathe with Tailstock

Innovative vertical turning-a new spin on your operations Boost your output at a price you’ll be surprised by with our vertical turning machines. Swiss Type CNC Lathe

Factories can achieve so much more with DAS vertical turning lathes. These lathes have the ability to work in a wide variety of materials and can handle really complex shapes. That is, companies would be able to create new sorts of products, or improve the products they already have. It’s like unlocking a special power at the factory that doesn’t limit you to any one crimping range again! Worm Whirlwind Milling CNC Lathe

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved