Then, at the other end of the spectrum, you have vertical CNC machines, such as those from DAS, and these are astonishing pieces of kit that can help to create all manner of products. These machines are operated by computer to control the tools that cut and shape metal and other materials. They’re essential for making pieces in companies like cars, airplanes and electronics. And now, we will discuss more cool things about vertical CNC machines.

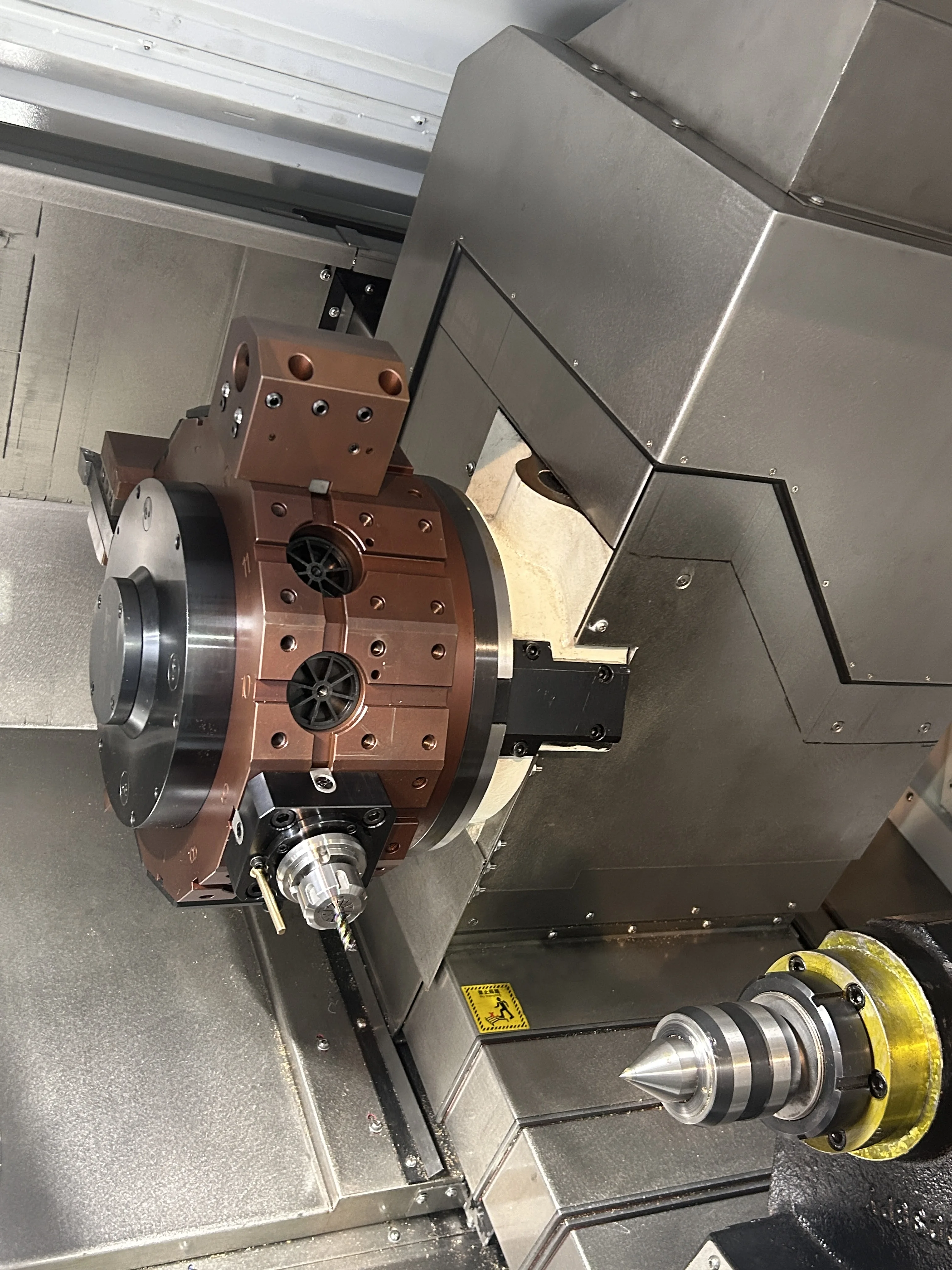

DAS Vertical CNC uses state-of the art technology to enable precise cutting of material. That means they are able to produce perfectly fitting parts. These are machines that move up and down (that’s what vertical refers to), and they can do really detailed work quickly. This makes it possible for factories to produce many high-quality products quickly, which is good for business.

What makes DAS’s vertical CNC machines unique is that they can be ushered into a customized mode to suit the demands of big buyers who require numerous products. These machines can also be programmed to perform various tasks, so they’re wicked helpful for large projects. That means if a company needs something really specific, DAS can build a CNC machine that does just that.

With durable construction and stable performance, these DAS vertical CNC machines are here to stay. They’re constructed out of robust materials that are able to withstand hard jobs over the long term. This is good for businesses because they don’t need to keep purchasing new machines. And these hardy machines can toil hard day after day without breaking down.

DAS is constantly coming up with new innovations for making inreasingly better their mill vertical center. They engineer their machines to move smoothly and quickly. This helps factories keep everything in motion, without any hiccups. The intuitive design also simplifies workers use of the machines, always a good thing.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved