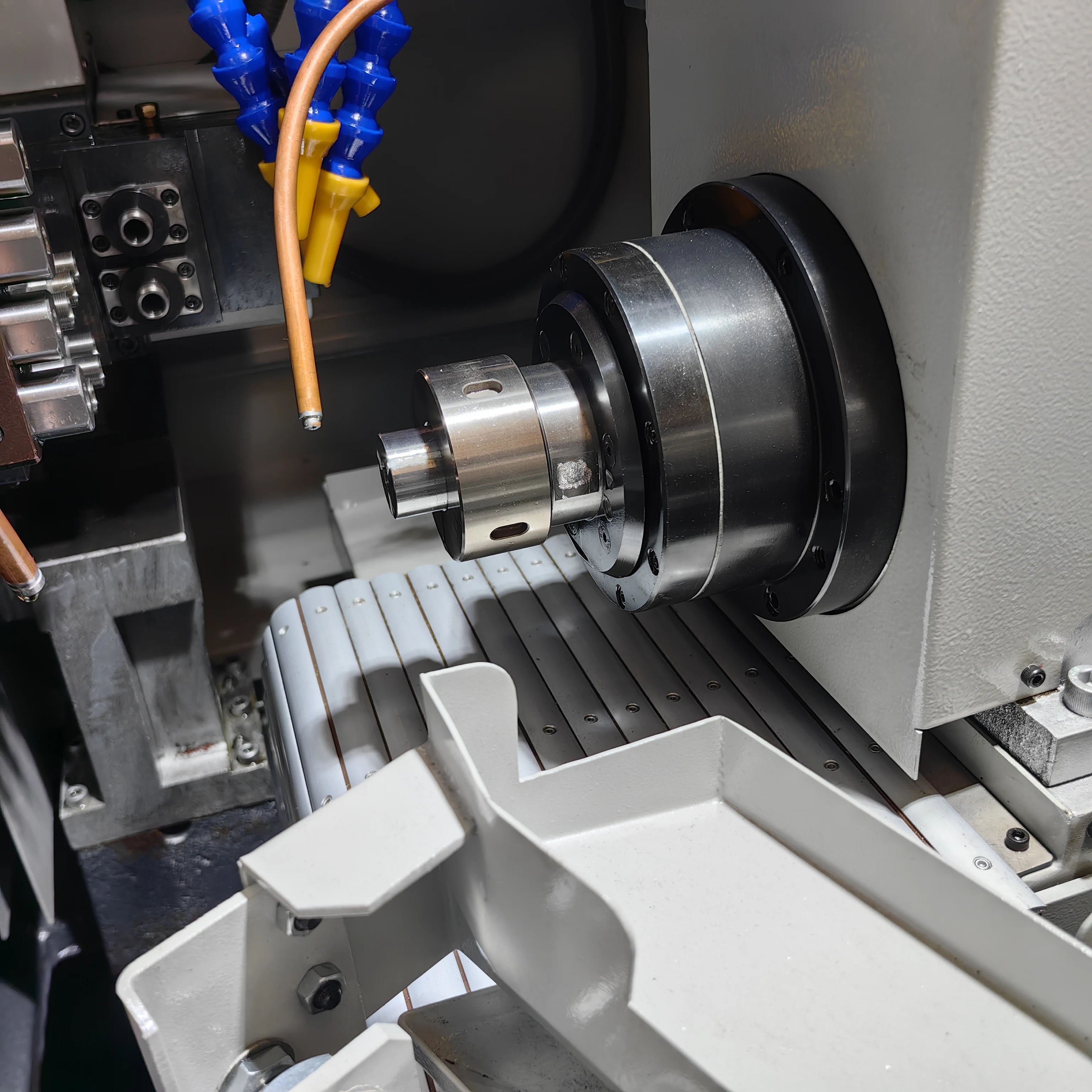

A twin spindle lathe can save time One of the very nice things about using a twin spindle lathe is that it can mean you’re saving your employee’s hours. With two spindles operating simultaneously, you can produce more parts in less time than with a single spindle machine. This enables meeting production deadlines and order fulfillment to be faster. Furthermore, double spindle lathes are reputed for high precision. This means you can get the parts you need with consistent quality and durability so there is less rework. With twin spindle lathes you can increase efficiency and maintain quality, which means your manufacturing process will work effectively.

Twin spindle lathe can also offer flexibility. These machines also frequently come equipped with state-of-the-art features and capabilities which can enable the production of a variety of parts. Whether you require complicated shapes, complex designs or simple part features, a two spindle lathe can machine a wide spectrum of parts. That kind of flexibility could make it possible for you to accept a wide range of jobs and respond to shifting customer needs. A twin spindle lathe gives you the ability to take on some of the biggest manufacturing challenges.DAS New Arrival Virtual Y Axis Power Turret CNC Lathe Turning and Milling Machine

If you are interested in buying twin spindle lathes for your factory, there is a wide range available. You can purchase directly from manufacturers, for example. You can pick them up twin spindle lathes for sale from many companies that focus on industrial machinery, such as DAS. Purchasing from the manufacturer directly can actually bring you competitive prices and availability to newer models, as well as newest technology. In some cases, manufacturers provide bulk purchase discounts to ease the cost of buying more than one machine at a time.

Another way to seek out the best deals on twin spindle lathes is through distributors or resellers. These are companies that purchase in bulk from manufacturers and then resell to customers at a markup. You might not have the kind of level of customization, service and support as you would when purchasing your twin spindle lathe from the manufacturer themselves; however buying through a distributor is easier – it’s a more straightforward process to get your hands on a 2 spindle lathe fast! They usually have a large variety of machines in stock and can assist you in seeking the best match for your needs.Foshan DAS Brand CNC Turning Lathe for Processing Worm Whirlwind Milling Numerical Control CNC Lathe Machine

With a twin spindle lathe there are a variety of advantages that can help to increase productivity in manufacturing. They save time and increase precision, while also offering flexibility so that you need only one in your shop. When looking to buy twin spindle lathes four bulk under one's shipping, supplier expectations and size of order will play a big factor in whether or not you want to get it directly from firms such as DAS or if they will utilize their distributor network to make a purchase. With the proper machinery, you can manufacture goods quickly and keep up with consumer demand.

There are a few things that you'll want to take into consideration when you buy a twin spindle lathe for your business, with the size and capacity of the machine being one key factor to keep in mind. You want to be sure that the lathe can support the size and weight of what you are planning on working with. You’ll also need to take into account speed and precision of the lathe, particularly in respect to how easily it can be operated and kept in good working order. You will also need to consider the price of the machine and whether it's in your budget range. All in all, you need to select a twin spindle lathe that will fulfill your distinct needs and requirements so as not only to make your business successful.

You have several options to improve the efficiency of your twin spindle lathe operation. For one, be sure that you are taking care of the machine regularly by cleaning and lubricating it on a regular basis. This can avoid malfunctions and ensure smooth operation. Also perhaps invest some time in training your operator so they use the lathe right, and efficiently. You could also consider the possibility of automation for more efficient manufacturing and added productivity. Doing so will help your twin spindle lathe reach its potential and assist your business in thriving.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved