Industrial companies, in particular, must have precision manufacturing systems as part of their manufacturing process to design appropriate parts for all kinds of applications. One such procedure that has seen growing favor over the last couple of years is Swiss Type CNC Lathe with Double Spindle Swiss Type Machine. This state of the art technology makes it possible shape and cut materials in order to produce sophisticated industrial parts. At DAS, we specialize in delivering the CNC turning solution that suits our customers' requirements best. We are a known name in producing quality components at the most competitive prices among CNC turning shops, our dependable work process and quick delivery, we are a best choice for wholesale buyers.

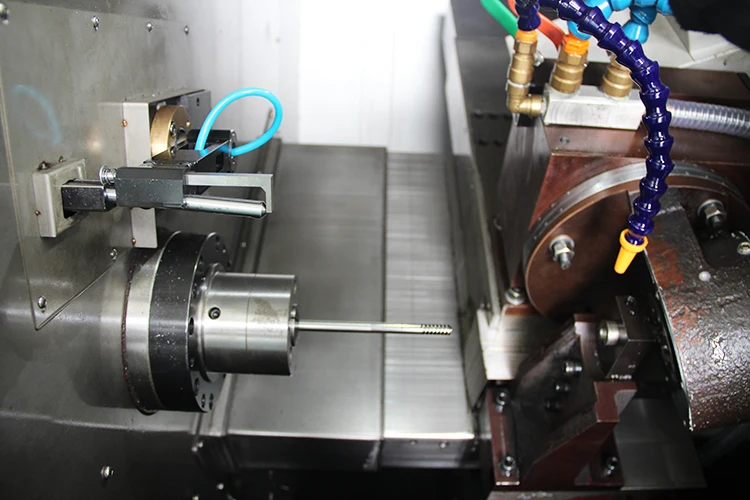

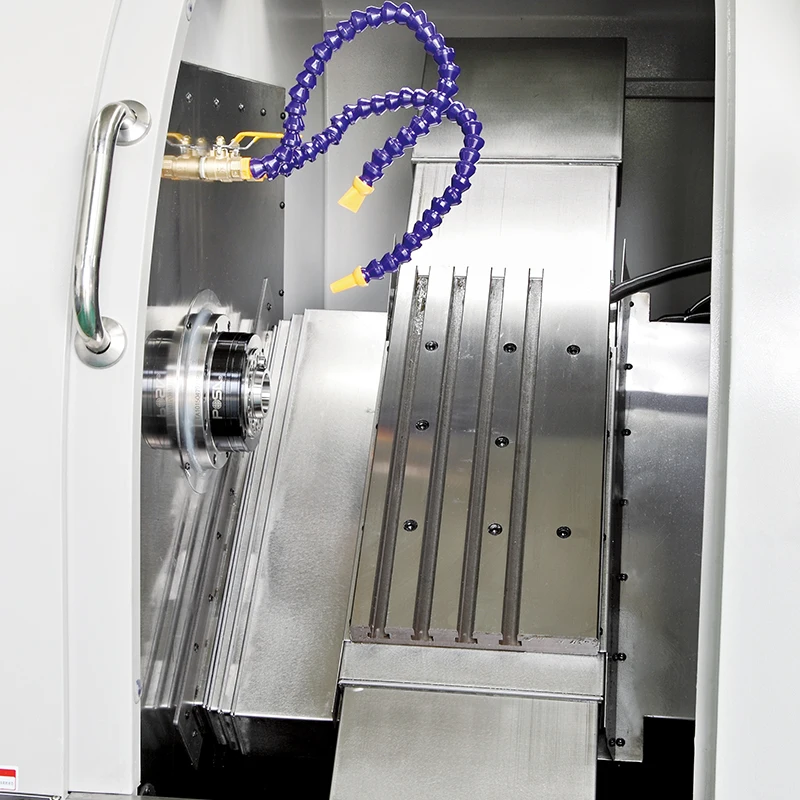

Nothing is more important in the production of industrial parts that are up to the highest standards for quality than precision. With CNC turning, we can provide accuracy that was previously impossible. Computer-controlled machines spin and shape raw materials, such as metal or plastic, to tight tolerances and smooth finishes. At DAS, we know accuracy is key in industry, outfitting our shop with top-of-the-line CNC turning machines to make certain that every part produced is consistent and products are as good as its blueprints.

In this rapidly-moving realm of industrial production efficiency is key. Which is why we use state of the art CNC tech to make our process as efficient as possible and reduce waste! CNC turning enables us to automate many aspects of machining, which minimizes the reliance on man-hours and improves the speed and precision of manufacture. We can literally program our CNC machines to build the most challenging of turned parts with minimal human control and not only will they produce these parts faster, but also consistently. Not only does this save you time and money, it enables us to help meet the strictest of deadlines and deliver those high-volume orders without compromising on quality.

Industrial Parts: Different Strokes for Different Folks Like snowflakes, no two industrial parts are alike. Which is why we have custom CNC turning services, which can be customized to best fit our clients. Whether you’re in need of custom parts that can meet a certain size, material, or shape demand, our company specializes in building parts that can meet your exact needs. Regardless of size or complexity, we can take your project from prototype to production. At DAS, we know that a one-size-fits-all philosophy just doesnt work so we take a custom approach to CNC turning so our customers receive exactly what they need.

In manufacturing, where many plants live on tight deadlines and in-plant mistakes can be expensive, reliability is crucial. Which is why at DAS we are so committed to our dependable production process and quick turnaround times. Each part that our expert machinists and engineers deliver is guaranteed to meet the highest of standards for accuracy and quality. Using new technology without abandoning old world methods, we’ll produce the quality parts that you need, on-time and within budget - every time. Whether you require a small prototype run or a full production run, DAS will deliver the results you require when you need them.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved