In the fabrication of parts, accuracy is of paramount importance and that is where precision CNC machining is a heartthrob. At DAS we have state of the art CNC milling and turning and we can produce high precision, close tolerance parts. Pressure Testing Machines Combining micromolding, autoclave curing of composites, investment casting, and other process development, pressure test specific machines ensure that you get the high-quality parts you need. We strive to be reliable and offer consistent results at competitive costs with quick turnaround time on all CNC machining service project. Quality Our industry-leading scrubber part quality control standards will deliver you the best scrubber parts that meet your needs!

High-precision CNC machining is a type of manufacturing that uses computer numerical control (CNC) to produce tight tolerance components with increasingly-rigorous design standards. This cutting ensures the raw material is in the correct shapes and sizes according to the customer's specifications. We are DAS - Machining for the world's most demanding industries, the true workhorse of manufacturing. With our top of the line equipment and experienced technicians we are able to make the finest parts that exceed the toughest of the industry standards.

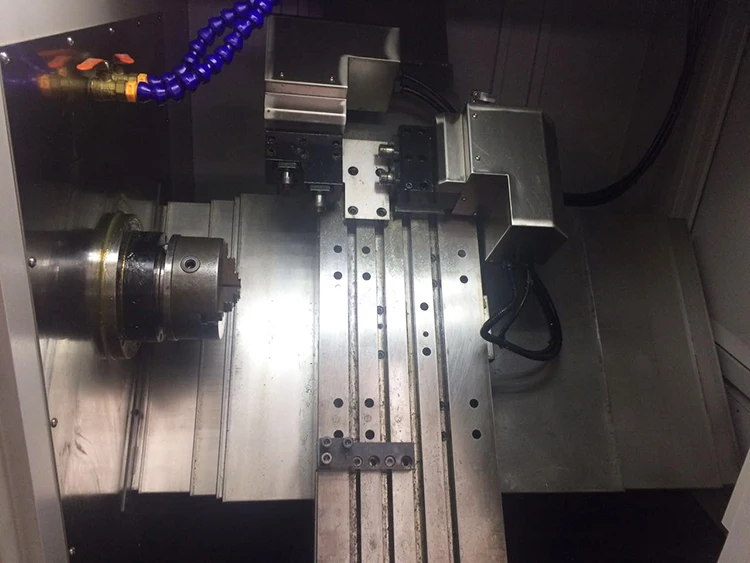

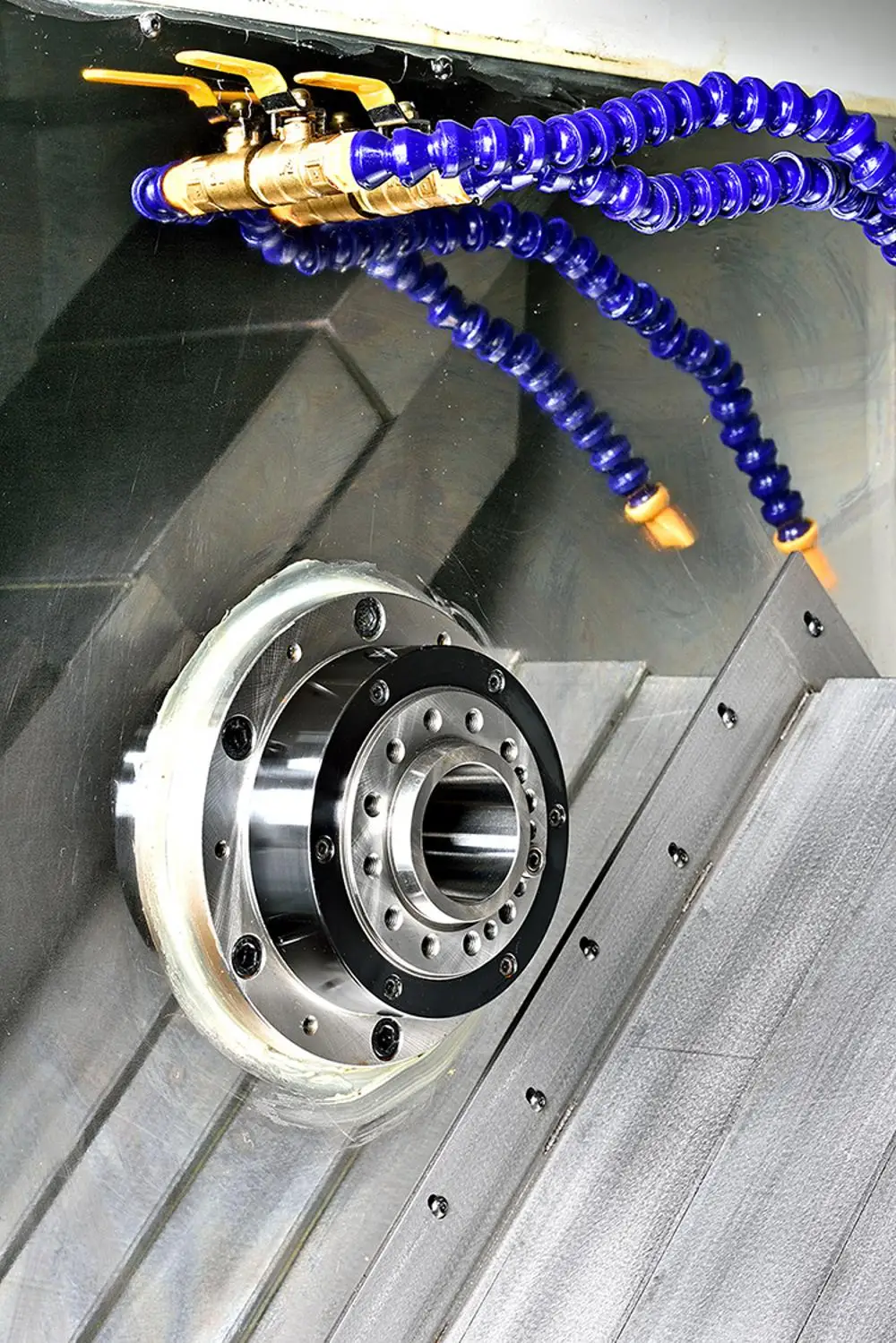

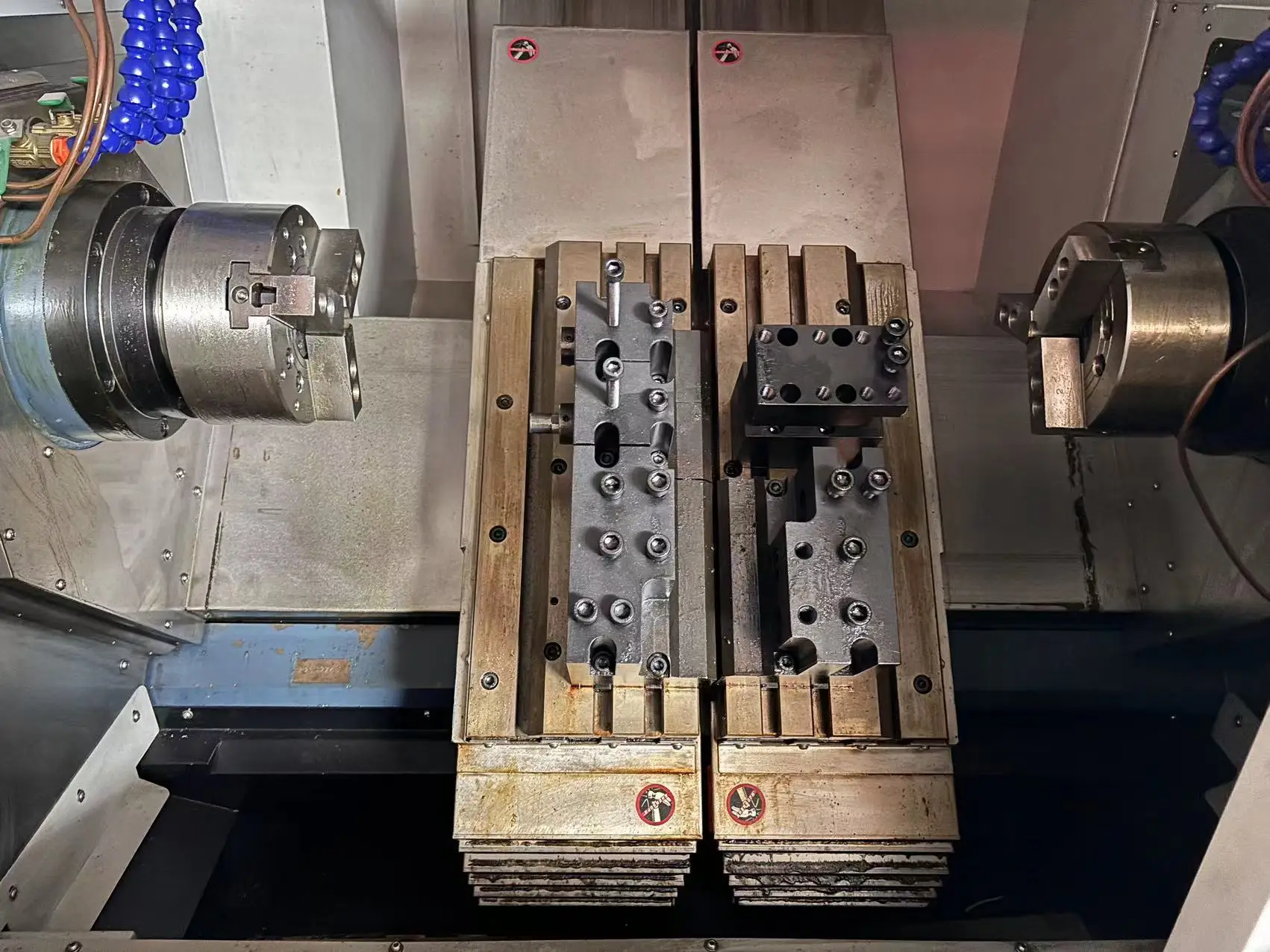

CNC milling and turning are among the most prevalent methods for precision machining. CNC milling is a machining process that removes material from the workpiece by rotating multi-tooth cutting tools. CNC turning, on the other hand, is when the workpiece is spinning, and a cutting tool with one point cuts away material, making cylindrical parts. At DAS, we have implemented the latest CNC milling and turning machines to improve our machining services. With our capabilities we have more possibilities to machine complicated parts with strict tolerances and excellent surface finish.

Whether you are prototyping for concept and validation or need a few parts for production, or hundreds of production parts, DAS can customize a solution that meets your need. Our in-house engineering and technical support staff, as well as our customers, collaborate on the best solutions for their requirements. We can provide help from choosing the right material to design optimization of the products that best suits your needs and economy. Our reputation for quality and invention makes us the go-to partner for all your machining needs.

We know that meeting a deadline and staying within budget is paramount at DAS. It’s why we provide quick turnarounds and cost-effective prices on all of your CNC machining projects. Enhanced efficiently: We can provide the outstanding parts in a very short period of time through the workflow. Whether you are looking to produce a small or large qty, we can do it without sacrificing quality. You can rely on DAS to get your CNC projects completed, on time and on budget.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved