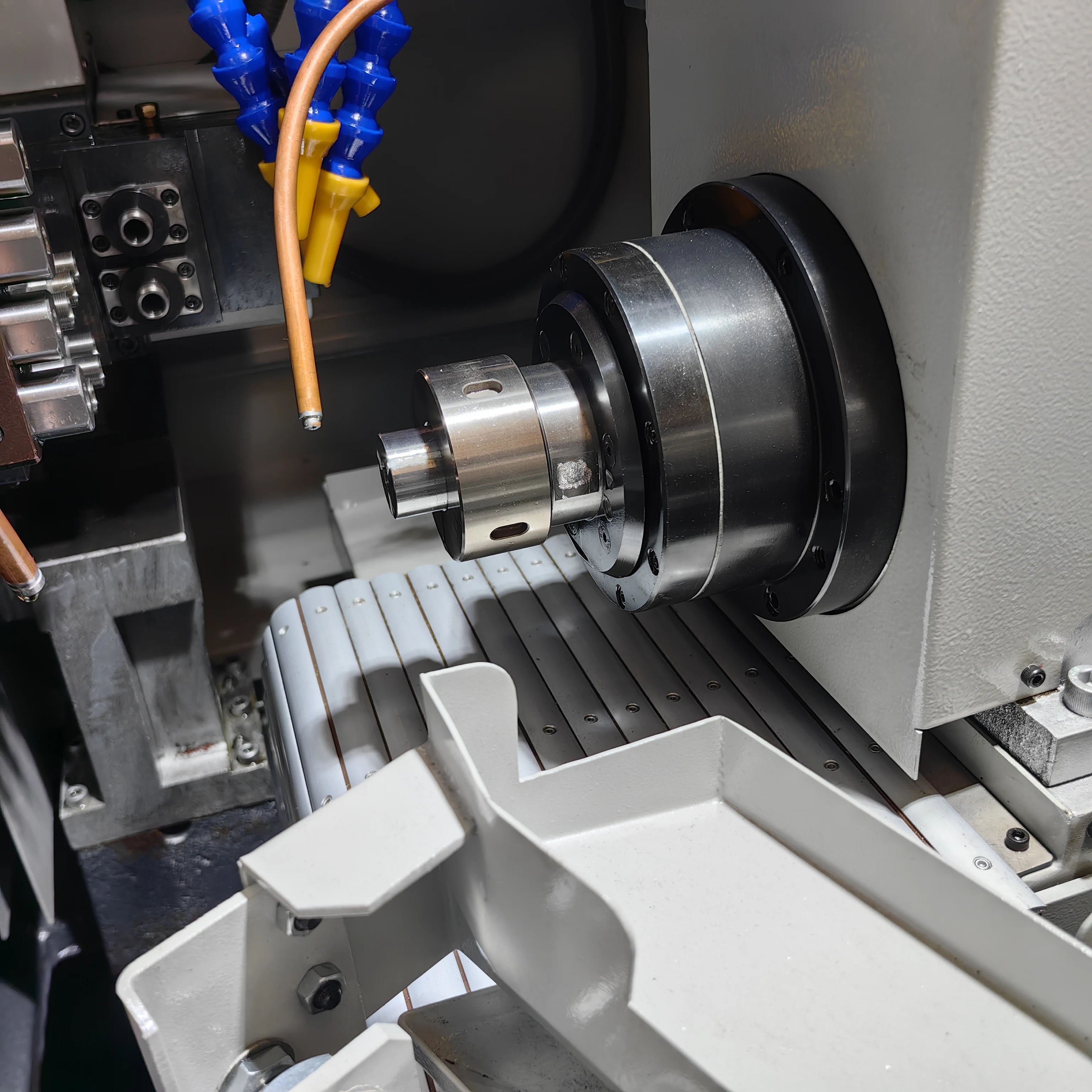

live centers for cnc lathe machines- high-performance_tooling Accurate Live Centers High quality live center is an important part in the processing of high-precision machining. They are used in various machining applications, such as the support for workpieces during turning or milling operation and the support for drilling workpiece. DAS,The leading figure of Gang Type CNC Lathe in the market. DAS can provide all kinds of quality live centers to meet your different needs for CNC lathe.

High precision and durable live centers for automatic lathe machines DAS knows that nothing less than the best materials and most innovative manufacturing process will ensure that their live centers are tough enough to handle industrial use. Premium resiliency live centers will help the manufacturer reduce downtime, simply by executing good machining practice and hold a better finish on their parts.

Among the typical everyday problems for live centers for CNC grinders is the normal amount of wear and tear they receive. This may result in poor accuracy and performance as well as high maintenance cost. One of the biggest challenges, and the easiest to forget when you are deep into production mode, is that live centers do wear out over time so it’s important that operators check them every day or two and replace as necessary. With high-grade live centers from DAS, you're less likely to have early wear issues and otherwise should expect superior performance for the long haul.

One of the common problems with live centers for CNC lathes is not being well lubricated, leading to friction, heat generation and failure. To avoid this, operators must lubricate according to the manufacturer’s recommendations and keep their live centers in good working order. DAS offers some great advise about keeping your live centers well lubed for smooth operation and longer life. Following these tips minimizes expensive damage and downtime, as well as maximizes the performance of your CNC lathe machine.

Live centers are an essential component in CNC lathes. Top Live Center Products Designed for CNC Laths The premium trending live center products for CNC lathes are durable, precise, and versatile. Live center we offer a wide range of live centers to suit the requirements of different applications for machining. Some of the hot-selling live center products from DAS include high precision live centers, extended nose life centers and heavy duty live centers. These live centers are constructed in high grade material to guarantee maximum performance and durability. No matter if you are doing small hobby projects or industrial production, with DAS live centers you always have the ideal Live Center for your CNC lathe.

Care and maintenance of Live Centers is necessary to prolong the life and maintain accuracy. To ensure your live centers are operating at their full potential, these should be cleaned and lubricated often. Clean any debris or chips from the live center with a soft brush and lubricate it slightly so that it rotates freely. Also, make sure to inspect the alignment of the live center time to time for accuracy. At the first sign of wear or damage, replace the live center at once to prevent further harm to your CNC lathe. By taking care of your live centers in this manner, you can be assured that they will last for many years to come.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved