CNC milling machines are used in the manufacturing industry and one of the most important components of a machine is the axis. CNC milling machine axis refers to the direction the processing tool is removed, and it is different from other machines. It is essential to know the axis of a CNC milling machine in order to use it properly and create quality parts. Now that the basics are out of the way, what are some of the benefits to Gang Type CNC Lathe and how can this benefit your production process?

The CNC mill axis can be the crucial factor to give the more or less flexibility and accuracy of a CNC milling operation. MachineCutting from CNC A multi-axis machine has cut into the world of conventional machining thanks to the arrival of CNC milling machines. For instance, a 5-axis CNC milling machine can move the tool in five directions enabling it to achieve intricate designs and finish. This feature decreases the need for manual handling and lowers errors to improve product quality. The spindle of a CNC milling machine facilitates simultaneous machining from different angles, which makes the manufacturing process faster and more efficient.

Efficient in Production Process The axis of a CNC milling machine is a revolution. With the use of multiple axes, components can be finished in one operation without part repositioning and downtime. Not only does this efficient workflow speed production, it also improves product quality and repeatability between batches. Additionally, CNC milling machines feature an axis that permits prolonged machining time and increased production capability. With the ability to carefully control movement of cutting tools, manufacturers can hold these tolerances and retain surface finishes that will keep its most particular customer satisfied. Ultimately, the axis of CNC milling machine is turning the way we make products faster and with better quality than ever.

the CNC milling machine axis is a very important role in promoting the efficiency and accuracy of manufacturing. Taking advantage of the benefits multi-axis machining offers allows manufacturers to increase productivity, decrease production costs and remain competitive in the current fast-paced market. Understanding the constraint system of a CNC milling machine axis is most important to open up new vistas and attain more success in industrial machining.

If you are in search of CNC milling machine axis suppliers, make sure that you engage a trustworthy and reputable company that provides quality products. DAS is a reliable China supplier of CNC machining S which offers global business customers high quality machines to help them meet their production requirements. DAS provides multiple axis selections to meet various machining requirements so that customers can get the perfect solution for their application.

The CNC milling machine market is constantly changing, with new developments and advancements being added to the marketplace every single year. CNC Milling Machine Axis Technology Advances CNC milling machines have several orders of technology advancement and the last one on that list is automation. This encompasses computer programmes for automation of machining and robotic arms, artificial intelligence to maintain efficiency and accuracy in machining.

A further development relating to the CNC milling machine axis design is characterized by the trend towards compact and lightweight axis design. Such new designs provide greater flexibility in machining processes and, as a result, allow for the easier invention of complicated parts more accurately. And further materials-science innovations are used to perfect the strength and durability of our axis part, offering ever-reliable long-term performance.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

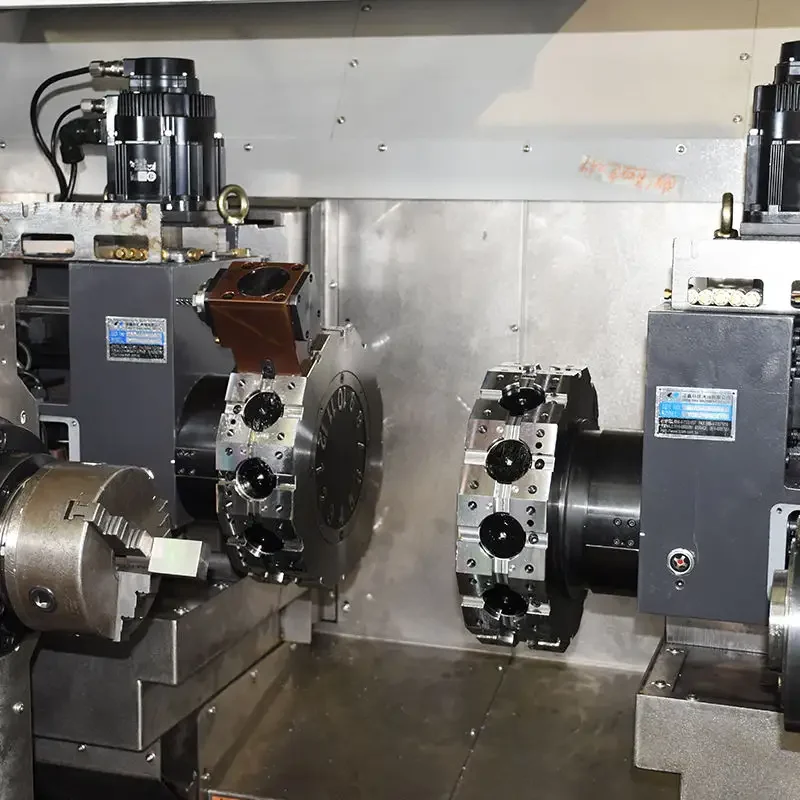

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved