CNC Lathe Tooling – High Performance Turning Tools Those who have had experience with production turning know the problems associated with chatter and vibration while machining a workpiece.

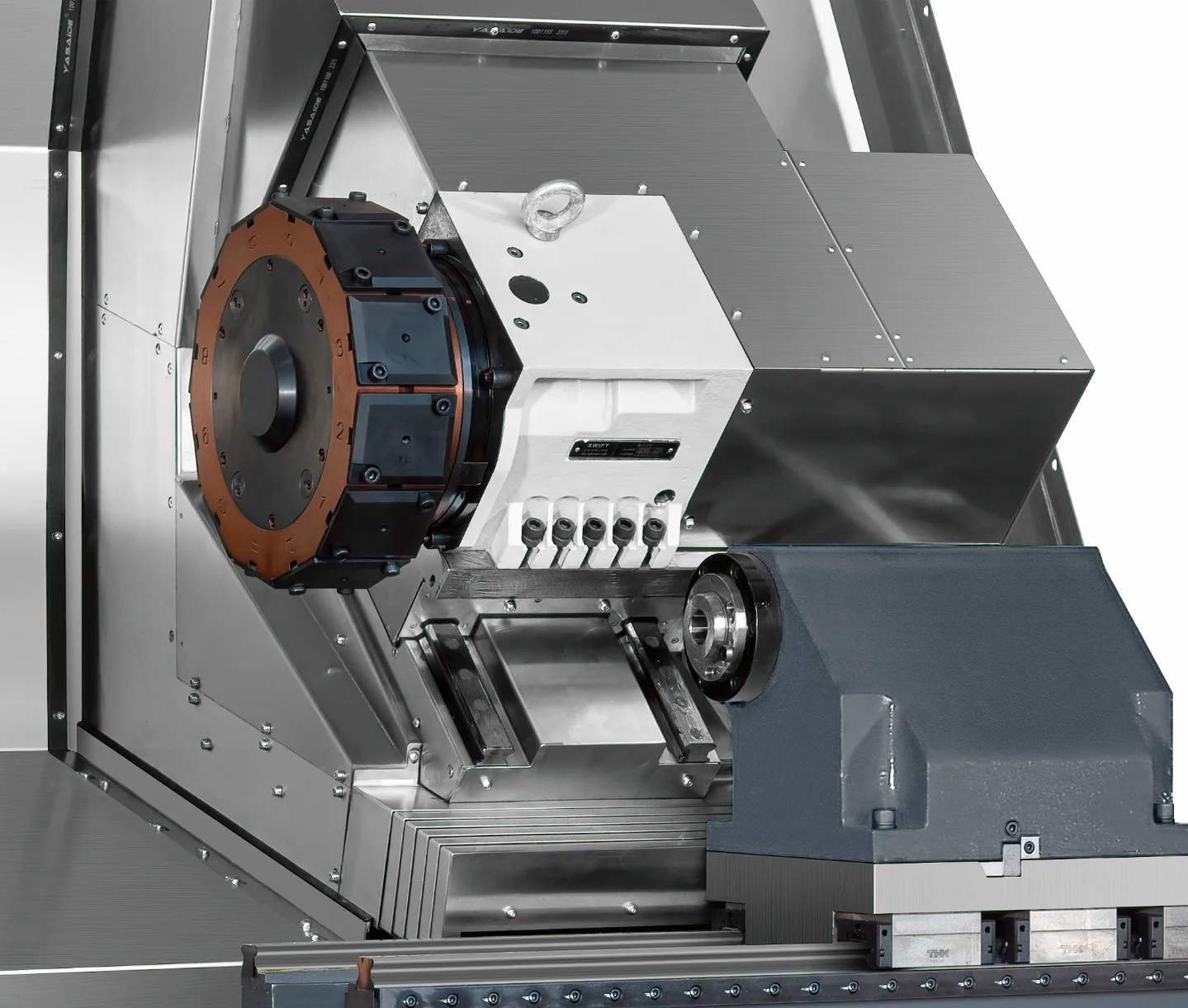

The right tools matter in precision manufacturing. CNC Lathe Tooling Keeping Production On Schedule CNC lathe tooling is essential to keeping parts production moving in an efficient, and accurate manner. At DAS we know the value of putting the best into something to get the best out of it. Our cnc lathe tooling is built to accommodate small to large deliveries and offers a comprehensive selection to support the myriad of needs facing today’s modern environment. With expert advice and support – from personalized solutions to extra engineering assistance – we are committed to improving machining performance for all our customers.

At DAS we pride ourselves in providing our customers with quality, affordable solutions to help them solve industry-specific problems. Our line of CNC lathe tooling is manufactured to exacting standards, to provide for a long life during continuous machining in manufacturing. There is an increased capability to operate more efficiently, reduce downtime, and experience a higher rate of production with our products like you’ve invested in. Through quality and performance we are striving to be the most trusted partner for businesses, who wish to gain added benefits of efficiency and success in precision manufacturing.

One of the top advantages of DAS is our massive variety of CNC lathe tooling for multiple applications. No matter if our customers are in aerospace, automotive, medical, or any industry, we have the specialty cutters they need to get the job done right. From turning inserts to turning tool holders, we provide a wide variety of tools that are tuned to work under the exact conditions of each application. We are a one stop shop for the perfect product and superior service for all their precision manufacturing needs.

Not only do we offer top of the line products, but we provide specialized tools for the application while also engaging in our “reverse engineering” assisting with new and existing projects! Our specially trained staff is ready to help you find the tools you need for your next project! Whether consumers have technical questions, a need for replacement parts, or help resolving issues, our team of professionals is available for direct contact. Leveraging our know-how and skills, we strive to help our customers get the most out of their CNC lathe tooling, and to realize their manufacturing objectives in the highest levels of precision.

Supported by 50+ applied patents and an open CNC system platform, we deliver tailored automation solutions for sectors such as energy, automotive, and medical devices—enabling efficient, precise mass production and lowering the technical barrier for cross-field adoption.

Strategically located in the Pearl River Delta's commercial hub with a total area of 28,000 square meters (including a 17,000 square meter plant under construction), we offer strong logistical advantages and scalable production capacity to serve diverse industries.

Founded in 1992, we have over 30 years of experience specializing in the design and manufacturing of unmanned and intelligent CNC production equipment, integrating R&D, production, and after-sales to accelerate the implementation of Industry 4.0 solutions.

Our products hold major international certifications including EU/CE, ISO9001, ISO14001, SGS, and EAC, and we provide modular machine tool designs that allow for rapid customization of turrets, spindles, and bed lengths to suit specific industrial applications.

Copyright © Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. All Rights Reserved